- Industrial machines and equipment

- Printing, Marking and Engraving

- Fiber laser marking machine

- Wuhan SWT Laser Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

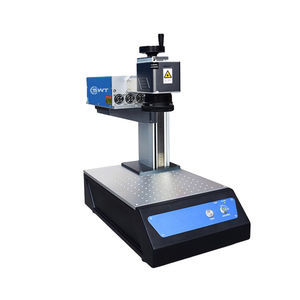

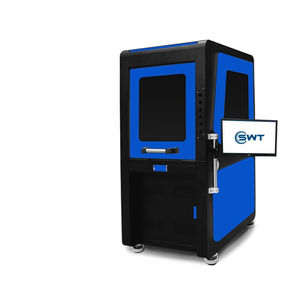

Fiber laser marking machine DB-01 30wbrassfor metalstone

Add to favorites

Compare this product

Characteristics

- Technique

- fiber laser

- Material

- brass, for metal, stone

- Applications

- for the automotive industry, barcode, for aluminum profiles

- Other characteristics

- high-accuracy, WiFi

- Power

Max.: 200 W

(0.27 hp)Min.: 20 W

(0.03 hp)30 W

(0.04 hp)- X travel

Max.: 300 mm

(11.81 in)Min.: 70 mm

(2.76 in)100 mm

(3.94 in)- Y travel

Max.: 300 mm

(11.81 in)Min.: 70 mm

(2.76 in)100 mm

(3.94 in)- Speed

Max.: 16,000 mm/s

Min.: 7,000 mm/s

12,000 mm/s

- Depth

Max.: 3 mm

(0.118 in)Min.: 0.1 mm

(0.004 in)0.1 mm

(0.004 in)

Description

Fiber laser split marking machine is a cutting-edge technology used for marking on various materials with high precision and speed. This machine utilizes fiber laser technology, known for its efficiency and durability, making it a popular choice for industrial applications. The split design of the machine allows for easy integration into production lines.

Characteristics of fiber laser split marking machine:

1. High precision: Fiber laser technology enables precise marking on a wide range of materials, including metals, plastics, and ceramics.

2. Fast marking speed: These machines are capable of high-speed marking, making them suitable for high-volume production environments and increasing throughput.

3. Low maintenance: Fiber lasers have a long lifespan and require minimal maintenance, reducing downtime and operating costs for businesses.

4. Compact design: The split design of the machine allows for easy installation and integration into existing production lines, saving space and optimizing workflow.

Application scope of fiber laser split marking machine:

1. Automotive industry: Fiber laser split marking machines are commonly used for marking on automotive components, such as engine parts, chassis, and gearboxes.

2. Electronics industry: These machines are utilized for marking on electronic devices, circuit boards, microchips, and other electronic components.

3. Medical industry: Fiber laser split marking machines are essential for marking medical devices, surgical instruments, implants, and other medical equipment.

4. Aerospace industry: These machines play a crucial role in marking on aircraft components, such as turbine blades, fuselage panels, and landing gear.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Wuhan SWT Laser Technology‘s catalogsOther Wuhan SWT Laser Technology products

Laser Marking Machine

Related Searches

- Marking machine

- Laser marking workstation

- Metal marking workstation

- Benchtop marking workstation

- Plastic marking workstation

- Industrial marking workstation

- Automated marking machine

- High-speed marking machine

- Compact marking workstation

- Fiber laser marking machine

- Laser engraving system

- Aluminum marking workstation

- Integration marking machine

- Air-cooled marking machine

- Hand-held marking machine

- Electronic component marking machine

- Wood engraving machine

- CO2 laser marking machine

- Industrial engraving system

- Marking and engraving system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.