- Metrology - Laboratory

- Metrology and Test Equipment

- Diameter measuring system

- Wuxi Frederick Measurement and Control Instrument Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

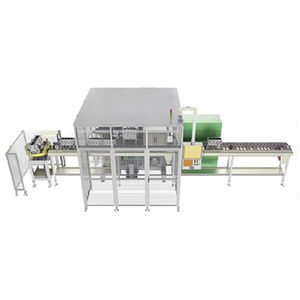

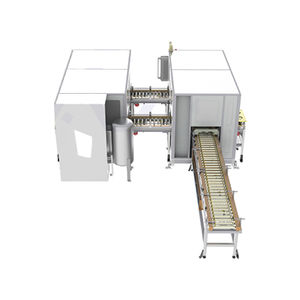

Connecting rod measuring machine diameterroundnesscylindricity

Add to favorites

Compare this product

Characteristics

- Measured physical value

- diameter, roundness, cylindricity

- Measured material

- connecting rod

- Applications

- for the automotive industry

- Other characteristics

- high-precision

Description

Connecting rod measuring machine can automatically weigh the big and small heads of connecting rods and realize the automatic measurements of the following items: bore diameter, roundness and cylindricity; Centre-to-centre distance between two bores; curvature, distortion and thickness. It also has the following functions: SPC analysis of the above measurement data; issue warnings to pre processing equipment, to avoid nonconforming; automatic imprinting of identification codes in accordance with measurement results; connecting rods of different groups can be sent to the corresponding material path, which greatly facilitates packing up.

Technical parameters

Measurement principle: Comparison measurement. Displacement sensor is used to measure the difference between the measured parts and the calibration parts, and then the relative sizes of the measured parts are calculated. The whole control system adopts Profinet bus communication mode for OPC communication with the host computer. The integration is strong and the communication is safe and reliable.

Measurement range: Manual adjustments for various sizes measurements. Centre-to-centre distance: 120mm-150mm, large bore inner diameter: 40mm-60mm, small bore inner diameter: 15mm - 30mm, big end thickness: 18mm-30mm.

Measurement takt time: ≤10 seconds, under normal condition and operation

Measurement position technology level: sensor resolution: 0.0001mm, measurement accuracy: 0.001mm, GRR: ≤10%.

Technical characteristics

•High measurement precision

•High measurement accuracy

•High measuring efficiency: 18 sec / piece

•Greatly reduce labor costs

Other Wuxi Frederick Measurement and Control Instrument Co., Ltd. products

Automation

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- Industrial gauge

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Automatic measuring device

- Benchtop measuring device

- Measuring device with display

- Control measuring machine

- Non-contact measuring machine

- High-precision measuring device

- CMM

- Diameter measuring machine

- Video measuring machine

- Laser measurement system

- Geometry measuring device

- USB measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.