- Metrology - Laboratory

- Metrology and Test Equipment

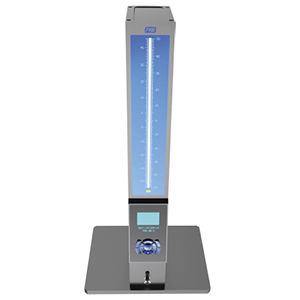

- Diameter measuring instrument

- Wuxi Frederick Measurement and Control Instrument Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Diameter gauge industrial

Add to favorites

Compare this product

Characteristics

- Measured value

- diameter

- Applications

- industrial

Description

Go-no gauge is used to test the inner hole diameter of cylinder. If the go end can go through the measured hole and the no go end can’t, hole diameter of the measured workpiece is qualified; if the go end can’t go through the measured hole or a part of the no go end can go into the measured part, hole diameter of the measured workpiece is unqualified.

Technical parameters

Scope of application:

1-Suitable for workpieces of which only the inner hole diameter need to be measured

2-Suitable for measurements of through hole, blind hole, step hole and semicircular hole (more than 180°)

3-Only used for measurements of parts of which hole diameter tolerance is more than IT8.

Technical characteristics

Three-color go-no gauge design standard & three-color go-no gauge with seam allowance design standard:

The corresponding standard handle is selected according to the different sizes of the basic size of the measured diameter;

The dimension of the connecting part of go end and no-go end and the work parts shall be designed according to the standard;

Diameter of the work part of the go end and no-go end shall be determined in accordance with the national standard GB1957-2006 Smooth Limit Gauge Technical Condition;

Shape error and surface roughness of the go end and no-go end shall be determined in accordance with the national standard GB1957-2006 Smooth Limit Gauge Technical Condition;

Three-color handle go-no gauge handle standard:

Handles of three-color handle go-no gauges are divided into five types according to the basic dimension of measured diameter;

Handles of three-color handle go-no gauges are divided into five types according to the basic dimension of measured diameter;

Other Wuxi Frederick Measurement and Control Instrument Co., Ltd. products

Gauge

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- Industrial gauge

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Automatic measuring device

- Benchtop measuring device

- Measuring device with display

- Control measuring machine

- Non-contact measuring machine

- High-precision measuring device

- CMM

- Diameter measuring machine

- Laser measurement system

- Video measuring machine

- Geometry measuring device

- USB measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.