- Metrology - Laboratory

- Metrology and Test Equipment

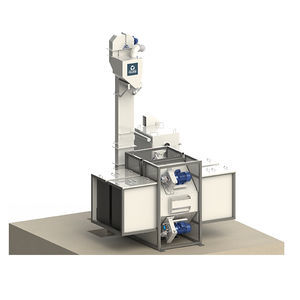

- Hydrostatic testing machine

- Wuxi Kelai NC Machine Tool CO.,Ltd

Hydrostatic test machine automaticcylinderhydrostatic

Add to favorites

Compare this product

Characteristics

- Test type

- hydrostatic

- Operating mode

- automatic

- Test material

- cylinder

- Technology

- hydrostatic

Description

The LNG cylinder production line of EN source company is used to store liquefied natural gas.

As we all know, liquefied natural gas is the most environmentally friendly and clean energy in the world, but the transportation and storage of natural gas is relatively difficult, and it needs to maintain a constant temperature or cryogenic(low temperature) environment.

The LNG projects provided by our company perfectly solve this problem.

Composition of LNG cylinder machinery production line

Winding machine

Outer tube grilling device

Shearing machine

Automatic flexible conveyor line

Helium mass spectrometer leak detector

Head assembly machine

Ultrasonic cleaning machine for pipe fittings

Molecular sieve oven

Welding workbench

Circumferential seam welding

Inner tank grilling device

Rolling machine

Automatic pressure test system

LNG cylinder vacuum system

Helium leak detection system

Cylinder cleaning machine

Insulation paper oven

Pass-through polishing machine

Annular joint flaw detector and lead room

Longitudinal seam welding machine

LNG cylinder machinery production line

Longitudinal seam welding machine

Scope of application:

This equipment is specially used for the longitudinal seam welding of the outer tank of LNG welding insulated gas cylinder.

Workpiece material: austenitic stainless steel.

Workpiece thickness: 2.5mm~6.0mm.

Weld joint form: I-type butt joint.

Diameter range: φ508mm~φ758mm.

Seam welding equipment for inner and outer bladder

Welding process and equipment characteristics:

Operation mode: simultaneous welding with two guns, single operation.

Equipment jacking pressure: not less than 3 tons (adjustable jacking pressure)

Catalogs

No catalogs are available for this product.

See all of Wuxi Kelai NC Machine Tool CO.,Ltd‘s catalogsOther Wuxi Kelai NC Machine Tool CO.,Ltd products

Machinery For Air Tanks

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.