RFI shielding EMIboard levelfor circuit boards

Add to favorites

Compare this product

Characteristics

- Options

- EMI, RFI, board level

- Applications

- for circuit boards

Description

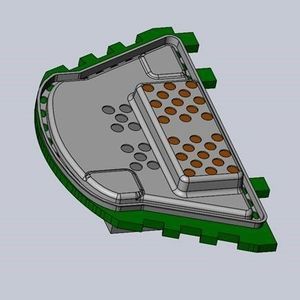

SnapShot EMI/RFI shields are custom designed, one-piece shields that are produced by thermoforming the shield in a custom mold. By using a mold, we can easily design in each shielded compartment to meet your design needs. These PCB multi-compartment EMI shields offer a lot of flexibility, which allows us to assure high level of customization, including cavities, ventilated holes for cooling, custom cutouts for cables and connectors, and mouse holes for trace entry/exit.

SnapShot board level shielding technology is capable of what we call “true multi-cavity” performance. We say this because the cavity to cavity isolation in a SnapShot multi-cavity EMI shield is equal the isolation between the external environment and the shielded cavity.

Adjacent cavities are isolated by leveraging the same solder sphere attachment mechanism between cavities as is used around the perimeter of the shield. This creates electrical contact to the ground plane between cavities on 1.8 – 2.0mm pitch; the same pitch as on the perimeter of the shield.

The design rule of having no points of EMI susceptibility greater then 2mm ensures excellent shielding effectiveness and isolation in the frequencies of greatest interest.

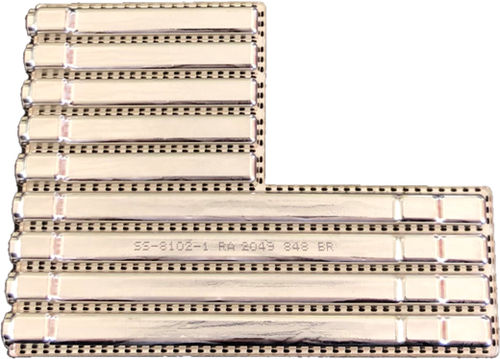

Here is an example of design that leveraged the multi-cavity capability to isolate nine transmit and receive channels:

Catalogs

No catalogs are available for this product.

See all of XGR Technologies‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.