RFI shielding EMIboard levelRF

Add to favorites

Compare this product

Characteristics

- Options

- EMI, RFI, RF, board level

Description

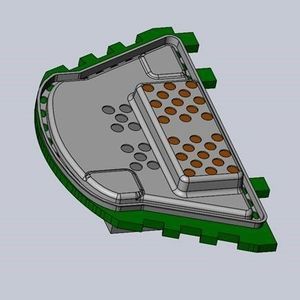

XGR Technologies specializes in the design and manufacturing of Snapshot ® board-level EMI / RFI shields, which are specifically built to your specifications. These custom board-level shielding solutions are created using an advanced thermoforming process, which allows us to assure the fastest turnaround times on these board-level shields. Over the years, we have invested in automated manufacturing equipment, engineering expertise, and resources, which allow us to deliver custom board-level shields on time and in quality, which remains unmatched. While many board level shield companies offer “custom” designed EMI shields, none compare in the design freedom offered by SnapShot board level shielding.

SnapShot custom board level EMI RF shields are manufactured by thermoforming a flat sheet of a metalized engineered polymer. By utilizing a thermoforming process, XGR is capable of producing EMI shields in virtually any shape to accommodate the customer’s board layout.

The process starts with an XGR engineer partnering with the customer to create a 3D model of the required EMI RF shield. Once this 3D model is created, it is incorporated into the customer’s design files in order to confirm there are no points of interference in the X, Y, and Z directions.

XGR then takes the 3D model of the shield and creates a machined metal mold for manufacturing the custom designed EMI shield for each unique customer application.

With this technology, XGR is able to provide custom board level shielding that maximizes the efficiency of board space utilization. For example, XGR designed a round

Catalogs

No catalogs are available for this product.

See all of XGR Technologies‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.