- Machine-tools

- Machining Center

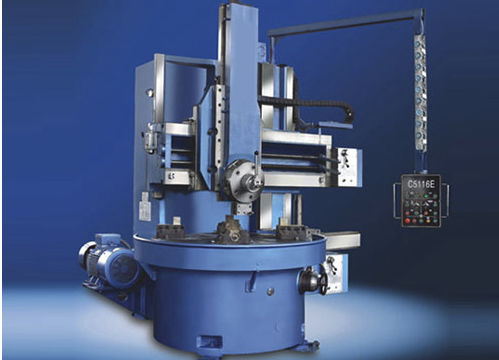

- Vertical lathe

- Xi'an Huayue Machinery and Equipment Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Conventional lathe C51 seriesverticalhydrostatichigh-precision

Add to favorites

Compare this product

Characteristics

- Control type

- conventional

- Spindle orientation

- vertical

- Structure

- hydrostatic

- Performance

- high-precision, high-speed

- Diameter

1,250 mm, 1,600 mm, 1,800 mm, 2,300 mm

(49.21 in, 62.99 in, 70.87 in, 90.55 in)- Spindle speed

Max.: 120 rpm

(753.982 rad.min-1)Min.: 3.1 rpm

(19.478 rad.min-1)

Description

Main features:

1)This series of machines have the conventional type and CNC type .It is suitable for finely and roughly machining of the internal and external cylindrical surface,inside and outside taper,surfacing,grooving of the ferrous metals,nonferrous metals and some non-metallic materials with high-speed steel,carbide cutting tools.

2)The main transmission of the vertical lathe is performed by vector inverter system,a continuously variable speed range can be obtained by 2 speed-shifting mechanisms.

3)The workable spindle is centered by high-precision double-row short cylindrical roller bearings of which the radial clearance is adjustable,the workable is equipped with constant current hydrostatic guideway,it is the thereby able to achieve a high rotary accuracy,large loading and small heart deformation.

4)There are two types of rail heads: In the first type the rail head equipped with pentagonal turret,while the side head with tetragonal turret;in the second type of rail head is equipped tetragonal turret,no side head.All head hesd balancing with hydrostatic tank,horizontal and vertical rapid feed could be a continuously variable speeds though AC servo driving .

5)The basic parts of the machine tools are all casted,processed and assembled in house.The casting material is high quality cast iron HT250 which has clear removed the casting stress thoroughly by annealing process and vibratory process.All the guideways of the bed column and beam have been supersonic frequency quenched.

6)Digital control and digital display could be equipped according to the request of customers.

Other Xi'an Huayue Machinery and Equipment Co., Ltd. products

Lathe machine

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- CNC milling machine

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- High-precision turning center

- Drilling machine

- Milling CNC machining center

- Column type CNC machining center

- Milling machine

- High-rigidity turning center

- Drilling CNC machining center

- 3-axis milling machine

- Machining center for the automobile industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.