- Production Machines

- Additive Manufacturing, 3D Printing

- Nickel 3D printing powder

- Xi'an Bright Laser Technologies,ltd (BLT)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Nickel 3D printing powder HastelloyX

Add to favorites

Compare this product

Characteristics

- Composition

- nickel

Description

BLT provides a variety of metal AM materials according to different categories, grades, particle size.

BLT powder grades encompass over 90% of commonly used metal AM powders, including Titanium and Titanium Alloys, Superalloys, Aluminum Alloys, Stainless Steel, and more. Additionally, BLT provides customized services to meet the specific requirements of our users for various metal AM materials.

BLTM Metal AM Powders

Adopt the optimized atomization process parameters, prepare the highly qualified AM titanium and titanium alloy powders

Component Detection

Equipped with CNAS certification testing center to strictly test the chemical composition of the powder

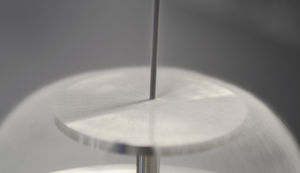

Morphology Detection

Detect and analyse the morphology and internal structure of the powder to provide a reference for the microstructure research of printed parts

Physical Property

Optimize the particle size distribution, fluidity and bulk density of the powder for additive manufacturing by milling process

Printing Verification

Various types of additive manufacturing equipment are used for verification of powder forming

Performance Testing

Comprehensively test the microstructure and mechanical properties of the formed parts to provide feedback for powder research and development

Powder properties:

• Good flowability

• In accordance With GB, ASTM standard chemical composition

• Uniform composition, high purity

• Grade : HastelloyX

• Product Specification : 0-20µm; 15-53µm; 53-105µm; 75-180µm

• Flowability : ≤30s

• Apparent Density : ≥4.1g/cm3

• Sphericity : ≥0.8

• Oxygen Content : ≤2000ppm

• Mechanical Properties (Annealing) : Tensile strength:690-750MPa; Yield strength:290-340MPa; Elongation:10-20%

Catalogs

No catalogs are available for this product.

See all of Xi'an Bright Laser Technologies,ltd (BLT)‘s catalogsOther Xi'an Bright Laser Technologies,ltd (BLT) products

Powders

Related Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- High-speed 3D printer

- Large-format 3D printing machine

- 3D printer for the aerospace industry

- 3D printing powder

- 3D printer for the automotive industry

- Laser sintering 3D printer

- Continuous 3D printing machine

- Mold manufacturing 3D printer

- Aluminum alloy 3D printer

- Stainless steel 3D printer

- Steel additive manufacturing machine

- Titanium alloy 3D printer

- Metal 3D printing powder

- Titanium 3D printing powder

- Aluminum 3D printing powder

- Nickel 3D printing powder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.