- Metrology - Laboratory

- Metrology and Test Equipment

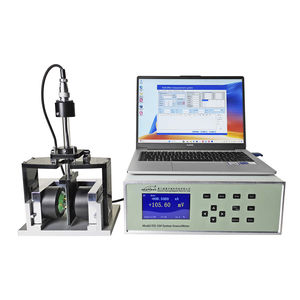

- Concentricity measuring system

- Xiamen Dexing Magnet Tech. Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Hall effect measurement system DX-1000Hconcentricityresistivityfully-automatic

Add to favorites

Compare this product

Characteristics

- Measured physical value

- Hall effect, concentricity, resistivity

- Operating mode

- fully-automatic

- Measured material

- for semiconductors

- Other characteristics

- high-precision

Description

DX-1000H High Temperature Hall Measurement Setup consists of an electromagnet, a vacuum pump, a high-temperature vacuum chamber, a Gauss meter, a constant current source, an electromagnet current source, a temperature controller, a computer and software.

Working principle of DX-1000H High Temperature Hall Measurement Setup

- The electromagnet current source provides current to the electromagnet to generate a magnetic field;

- The gauss meter measures the value of the uniform magnetic field generated by the electromagnet;

- On the one hand, the constant current source provides sample test current to the sample for Hall effect testing, and on the other hand, it is used to measure the Hall voltage fed back by the sample;

- The sample to be tested is placed in a high-temperature vacuum chamber, fixed by high-temperature glue, and used as four test points;

- There are 4 leads from the high-temperature vacuum chamber, two of which are connected to the temperature controller for temperature measurement and control, the other is the lead wire of the high-temperature probe connected to the Gauss meter, and the other is connected to the Hall sample connection wire to the constant current source ;

- The computer is connected to a gauss meter, a temperature controller, a constant current source and an electromagnet current source, and the software controls the current and magnetic field values passing through the sample being measured, and obtains the measured voltage value.

Testable materials of Hall Measurement Setup:

- Semiconductor materials: SiGe, SiC, InAs, InGaAs, InP, AlGaAs, HgCdTe and ferrite materials, etc.;

Catalogs

No catalogs are available for this product.

See all of Xiamen Dexing Magnet Tech. Co., Ltd.‘s catalogsOther Xiamen Dexing Magnet Tech. Co., Ltd. products

Hall Effect Measurement System

Related Searches

- Measuring device

- Measuring machine

- Digital testing system

- Automatic test equipment

- Optical measuring machine

- Automatic measuring machine

- Automatic testing system

- Industrial gauge

- Manual test kit

- High-precision measuring machine

- Industrial test equipment

- Measuring system for industrial applications

- Portable test kit

- Automatic measuring device

- Benchtop measuring device

- Benchtop testing system

- Non-contact measuring machine

- High-precision measuring device

- Battery testing system

- Laser measurement system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.