- Materials - Tools - Components

- Semi-finished products

- Ceramic sheet

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

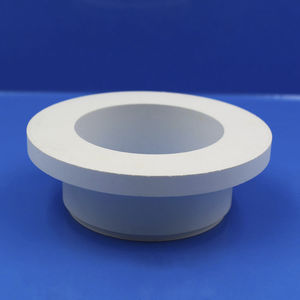

Ceramic plate INC-B001tuberodsheet

Add to favorites

Compare this product

Characteristics

- Shape

- plate, tube, rod, sheet

- Composition

- boron nitride

- Other characteristics

- high-temperature

Description

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite.

Material of Boron Nitride Ceramics

Pyrolytic Boron Nitride: 99.99% Boron Nitride*

99 Boron Nitride: Boron Nitride + Boric Oxide (B2O3)

CABN: Boron Nitride + Calcium Borate

ALBN: Boron Nitride + Al2BO3

ZRBN: Boron Nitride + Zirconium Oxide + Boric Oxide (B2O3)

ZABN: Boron Nitride + Zirconium Oxide + Aluminum Nitride + Al2BO3

SCBN: Boron Nitride + Silicon Carbon + Al2BO3

Processing of Boron Nitride Ceramics

Hot Pressed Sintering

Chemical Vapor Deposition

Applications of Boron Nitrides Ceramics

Thermal Management

Excellent electrical insulation and thermal conductivity make BN very useful as a heat sink in high-power electronic applications. Its properties compare favorably with beryllium oxide, aluminum oxide, and other electronic packaging materials, and are easier machinable to desired shapes and sizes.

High Temperature Environments

Temperature stability and excellent resistance to thermal shock make BN the ideal material in the toughest high-temperature environments such as equipment for plasma arc welding, diffusion source wafers, and semiconductor crystal growth equipment & processing.

Molten Metal Handling

BN is inorganic, inert, nonreactive with halide salts and reagents, and is not wet by most molten metals and slags. These characteristics, combined with low thermal expansion, make it ideal for interface materials used in various molten metal processes.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Boron Nitride Ceramic

Related Searches

- Ceramic

- Insulation ceramic

- Alumina ceramic

- Ceramic plate

- Tubular ceramic

- Substrate

- Ceramic rod

- High-temperature ceramic

- Protective ceramic

- Ceramic sheet

- Boron nitride ceramic

- Ceramic substrate

- Substrate for the electronics industry

- Zirconia ceramic

- Silicon nitride ceramic

- Ceramic stick

- Tile ceramic

- Thermal pad

- Ceramic pipe

- Thick-film substrate

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.