- Industrial machines and equipment

- Heat Exchanger and Refrigeration

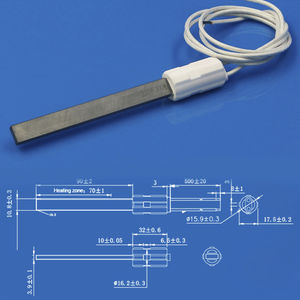

- Heating strip

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

Heating strip ceramicaluminaindustrial

Add to favorites

Compare this product

Characteristics

- Type

- flat

- Material

- ceramic, alumina

- Applications

- industrial, for 3D printing, for medical applications, automotive

Description

Alumina Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before. Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries.

Application of Alumina Ceramic Heaters

Automotive Components

Glow Plug

Igniter for Cabin Heater

Heater for Oxygen Sensor

Kerosene and Gas Appliances

Igniter

Heater for Vaporizer

Industrial Heater Applications

Heater for Soldering Iron

Heater for Hair Iron

Bonding Heater

Seal Heater

Water-Heating Applications

Heater for Toilet Water

Bath Water Heater

Steam Boiler Heater

Liquid Heater for Small Appliances

Advantages of Ceramic Heaters

Compact, Lightweight and Energy Efficient

Ceramic heaters feature high watt density and excellent thermal efficiency. Multiple heating elements can be layered into a single unit.

Superior Thermal Properties

Ceramic heaters reach high temperatures rapidly and are available with custom-designed heat distribution patterns. The material’s strong insulation properties permit direct contact with a variety of materials, including water, kerosene and metals.

High Reliability

Superior dielectric strength, electrical insulation and chemical resistance give Innovacera’s ceramic heaters outstanding reliability. Our oxidation-resistant material ensures a long service life.

No Electric Noise

Ceramic heaters produce no electric noise.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Alumina Ceramic Heater

Related Searches

- Resistance heater

- Tubular resistance heater

- Cartridge heater

- Flat resistance heater

- Ceramic resistance heater

- Flexible resistance heater

- Industrial resistance heater

- PTC resistance heater

- Compact resistance heater

- Tubular cartridge heater

- Custom resistance heater

- Igniter

- 230 V cartridge heater

- Plate heating element

- Round heating element

- Automotive heating element

- High-temperature cartridge heater

- Burner igniter

- Heating element for medical applications

- Liquids and gase heating element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.