- Hydraulics - Pneumatics

- Filter and Separator

- Gas filter

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

Gas filter INC-P003liquidprocessceramic

Add to favorites

Compare this product

Characteristics

- Designed for

- liquid, gas

- Applications

- process

- Material

- ceramic

Description

Innovacera uses its deep ceramics expertise and process capabilities to manufacture ceramics with precisely controlled porosity. Porous ceramics are often used for chemical filtration and fluid separation.

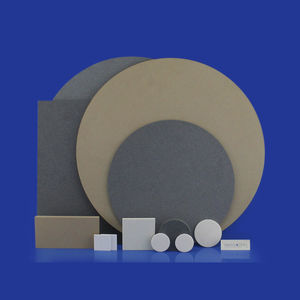

The range of Innovacera porous ceramics is made from aluminum oxide and silicon carbide. The strong, uniform porous ceramic has 40-50% open porosity with a tortuous pore structure and is available in pore sizes ranging from 1 to 100 microns.

Three Main Application of Porous Ceramic:

Vacuum Chuck, like scribing machine vacuum chuck, silicon wafer vacuum chuck.

Adsorption platform.

Suspension platform.

Especially, they are widely used for the semiconductor industry, like LED wafer processing.

The micro-porous ceramic working disk is a special tool for adsorption and bearing in various semiconductor wafer production processes, and is applied to processes such as thinning, dicing, cleaning, and handling.

They can be used with Japan, Germany, Israel, the United States, and domestic equipment, like Disco, ADT, K & S, Applied materials TSK, OKAMOTO, Micro Automation, Load Point.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Porous Ceramic

Related Searches

- Liquid separator filter

- Filter for industrial applications

- Gas pre-filter

- Process separator filter

- Vacuum separator filter

- Plate filter

- Disc filter

- Water treatment filter

- Wastewater treatment filter

- Corrosion-proof separator filter

- Solid separator filter

- Ceramic filter

- Sludge treatment filter

- Waterproof filter

- Industrial washing filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.