- Industrial machines and equipment

- Surface Treatment

- Hot dip metallization

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

Hot dip metallization INC-AMB001nickelaluminumautomotive

Add to favorites

Compare this product

Characteristics

- Process

- hot dip

- Type of substrate

- nickel, aluminum

- Applications

- automotive

Description

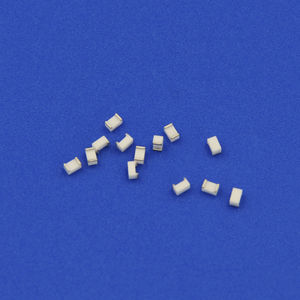

AMB Ceramic Substrate is a method to realize the bonding of ceramic and metal by reacting a small amount of active elements Ti and Zr in filler metal with ceramics to form a reaction layer which can be wetted by liquid filler metal.

Advantage:

The combination is achieved by chemical reaction between ceramic and active metal solder paste at high temperature, so its bonding strength is higher and reliability is better.

Disadvantage:

The reliability of AMB process depends largely on the composition of active filler metal, brazing process, brazing layer structure and many other key factors。

Specification

>Metallization thickness: 25 ±10um

>Nickel thickness:2~10um;

>Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Characteristics:

Specialized Alumina materials with high insulation resistance

High-reliability ceramic tubes. Mo-Mn metallization with nickel plating allows customers to assemble hermetically sealed products.

Joining types:

Ceramic + Mo/Mn Metallized + plating Ni

Ceramic + Mo/Mn Metallized + plating Ag

Ceramic + Mo/Mn Metallized + plating Au

Ceramic + printing Ag

Special types are available according to customer’s drawings or samples

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Metallized Ceramic

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.