- Materials - Tools - Components

- Semi-finished products

- Ceramic substrate

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

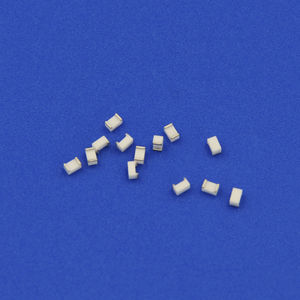

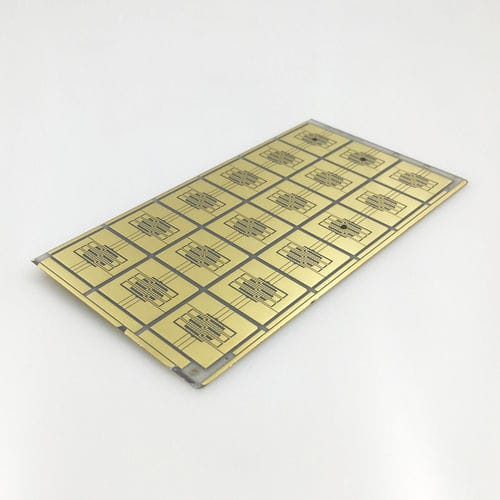

Ceramic substrate INC-DPC001

Add to favorites

Compare this product

Characteristics

- Options

- ceramic

Description

DPC (Direct Plated Copper) Introduction:

Mainly by evaporation, magnetron sputtering and other surface deposition process to carry on the substrate surface metallization, first under the condition of vacuum sputtering, titanium, and then is copper particles, the plating thickness, then finish making line with ordinary PCB craft, and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating, wet deposition,Exposure development, etching and other processes.

DPC Ceramic Substrate Advantages:

> In terms of shape processing, DPC ceramic substrate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine.

> The crystal performance of the metal is good;

> The flatness is good;

> The line is not easy to fall off;

> The line position is more accurate, the line distance is smaller, reliable and stable, can be through the hole and other advantages.

DPC Disadvantages:

It can only make thin plate (thickness < 300μm), and its cost is high, the output value is limited, resulting in frequent shipment time can not be on time.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Metallized Ceramic

Related Searches

- Ceramic

- Insulation ceramic

- Alumina ceramic

- Ceramic plate

- Tubular ceramic

- Ceramic rod

- Substrate

- High-temperature ceramic

- Protective ceramic

- Ceramic sheet

- Ceramic substrate

- Substrate for the electronics industry

- Silicon nitride ceramic

- Ceramic stick

- Tile ceramic

- Thermal pad

- Ceramic disk

- Ceramic pipe

- Wear-resistant ceramic

- Ceramic pad

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.