- Materials - Tools - Components

- Standard Mechanical Component

- Multiple-element feedthrough

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

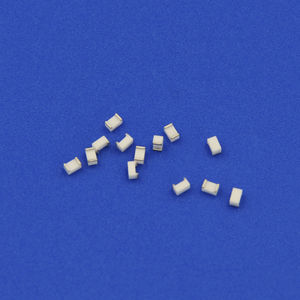

Welding feedthrough INC-M002multiple-elementheat-resistantfor the semiconductor industry

Add to favorites

Compare this product

Characteristics

- Product applications

- welding

- Configuration

- multiple-element

- Protection level

- heat-resistant

- Domain

- for electrical applications, for the semiconductor industry

- Other characteristics

- vacuum

Description

Mo Mn Ceramic Feedthrough Ceramic Vacuum Electrodes

The Ceramic Surfaces for Brazing, the surface must be metallized.

Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher.

Advantages of Ceramic-to-Metal Seals

* More solid, durable hermetic seal and better electrical insulation

* Used for more harsh conditions, such as high and low (cryogenic) temperature, corrosive, high pressure, and high vacuum environments

* High mechanical strength, less fracture when applied to high vibration and high g-load conditions

* Shows strong bond and an excellent seal with metals and alloys, such as copper and Cu alloys (CuNi) and to nickel and Ni alloys.

Application

> Feedthrough

> Metal /alloy ceramic metallized

> Screen Printing

> Roll Printing

> Hand Painting

> Air Brush Spraying

> Immersion

> Centrifugal Coating

> Needle Painting

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Metallized Ceramic

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.