- Production Machines

- Other Manufacturing Equipment

- Crucible

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

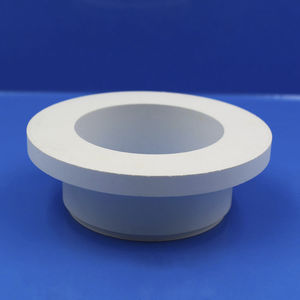

Boron nitride crucible INC-BN004

Add to favorites

Compare this product

Characteristics

- Options

- boron nitride

Description

Introduction of Boron Nitride ceramic crucible:

A boron nitride crucible, suitable for the vaporization of aluminum, having a multi-walled structure comprising an outer wall and a thinner inner wall weakly bonded to the thicker outer wall. Because of this structure, the crucible is considerably more flexible than conventional single-walled crucibles and exhibits substantially improved thermal cycling characteristics and longer life. The crucible is produced by depositing pyrolytic boron nitride upon a mandrel having the shape of the desired crucible at a temperature of from about 1850° C. to about 2100° C. until a first layer of boron nitride of suitable thickness has been produced, interrupting the deposition of boron nitride upon the mandrel and lowering the temperature to below 1750° C., and then depositing additional boron nitride upon the mandrel at a temperature of from about 1850° C. to about 2100° C. to produce a second outer layer of boron nitride having a thickness greater than that of the inner layer.

Features and Benefits of Boron Nitride ceramic

1. Easily Machinable

2. Exceptional Heat Resistance

3. High Thermal Conductivity

4. Low Thermal Expansion, Excellent Thermal Shock Resistance

5. Outstanding Electrical Insulation - even at high temperatures

6. High wet resistance to molten metals, slags and glass

7. Extreme Corrosion and Wear Resistance

8. for Sintering and Smelting Alloy

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Boron Nitride Ceramic

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.