- Materials - Tools - Components

- Semi-finished products

- Ceramic

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

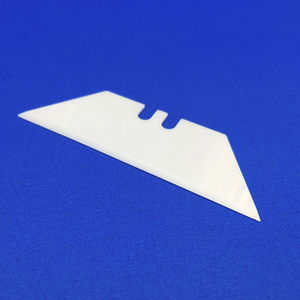

Zirconia ceramic

Add to favorites

Compare this product

Characteristics

- Composition

- zirconia

Description

Magnesia Stabilized Zirconia (MSZ) Ceramic is a great refractory and insulating material due to high oxygen ion conductivity, high strength and toughness, and good thermal shock resistance. It has a clean melt at temperatures above 1900°C and above and is specially manufactured for melting superalloys and precious metals. Its superior thermal shock resistance to temperatures reaching up to 2200°C.

Advantages:

High thermal shock resistance

High wear-resistant and erosion-resistant

Metal corrosion resistance in high temperature

Excellent non-wetting characteristics

High strength

Long service life

The stabilizers and grains combination can be designed according to customer’s using environment.

Application Temperature:

0°C-2200℃

Applicable Environment:

Air, Vacuum, or Atmosphere Protection Environment

Application Field:

High temperature melt flow control

Sizing nozzle, Ladle skateboard panel, Converter slag blocking slide plate and ring, etc.

Specialty glass manufacturing

Large size high content of zirconia and alumina ceramics, etc.

Metal powder industry

Setter plate, Gas atomizing nozzle, etc.

Precious metal smelting industry

Ceramic Crucibles, etc.

Artificial/Laser Crystal Ceramic Temperature Field

Rare earth composite oxide solid solution ceramic temperature field, etc.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Zirconia Ceramic

Related Searches

- Ceramic

- Insulation ceramic

- Alumina ceramic

- Ceramic plate

- Tubular ceramic

- Substrate

- Ceramic rod

- High-temperature ceramic

- Protective ceramic

- Ceramic sheet

- Boron nitride ceramic

- Substrate for the electronics industry

- Ceramic substrate

- Silicon nitride ceramic

- Ceramic stick

- Tile ceramic

- Thermal pad

- Ceramic pipe

- Ceramic pad

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.