- Products

- Furnace brazing

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

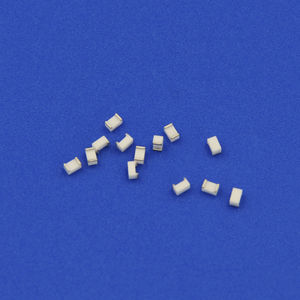

Furnace brazing

Add to favorites

Compare this product

Characteristics

- Other characteristics

- furnace

Description

The general process of brazing ceramics and metals can be divided into seven processes: surface cleaning, paste coating, ceramic surface metallization, nickel plating, brazing and post-weld inspection.

Surface cleaning is to remove oil, sweat and oxide film on the surface of the base material. Metal parts and brazing materials are first degreased, then pickled or alkaline washed to remove the oxide film, rinsed with running water and dried. Parts with high requirements should be heat treated in a vacuum furnace or hydrogen furnace (or ion bombardment method) at an appropriate temperature and time to purify the surface of the parts. After cleaning, the parts must not come into contact with oily objects or bare hands, and should immediately enter the next process or be placed in a dryer. They cannot be exposed to the air for a long time. Ceramic parts should be cleaned with acetone and ultrasound, then rinsed with running water, and finally boiled with deionized water twice, each time for 15 minutes.

Direct brazing

When brazing directly (active metal method), the surface of the ceramic and metal parts to be welded should be cleaned first, and then assembled. To avoid cracks in component materials due to different thermal expansion coefficients, a buffer layer (one or more metal sheets) can be rotated between welds. The brazing material should be sandwiched between the two welded parts as much as possible or placed in a position where the gap is filled with brazing material, and then brazing should be performed like ordinary vacuum brazing.

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Metallized Ceramic

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.