- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Ring heating element

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

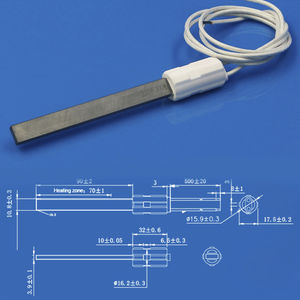

Ring heating element ceramiccompacthigh power density

Add to favorites

Compare this product

Characteristics

- Type

- ring

- Material

- ceramic

- Other characteristics

- compact, high power density

Description

Mass spectrometers are a technique for analyzing and identifying chemical substances by arranging gaseous ions in electromagnetic fields based on their mass-to-charge ratios.

Mass spectrometers can detect most analytes per borehole, so it is essential to have a non-contaminating heat source. In addition, competing requirements for instrument designs to reduce size and complexity while increasing sensitivity are being challenged.

Mass spectrometer heating elements, also called source heaters or gas line heaters, are used in mass spectrometers to turn the sample (typically in an aqueous or organic solution) into a vapor for analysis. Before the analyzer and detector areas, the heaters are part of the sample conditioning system, where the vaporized sample is then bombarded by ionized high-energy electrons and analyzed.

Heaters used in mass spectrometers are compact in design and provide a fairly high power density. They are fast responding and operate at temperatures up to 400 °C. They include internal temperature sensors for accurate control and limiting.

The INNOVACERA Advantage

Engineering Support for New Designs

Rapid Prototyping

Replacement Parts

Advantages of MCH heater

MCH ceramic heating element is high-efficiency, environmentally friendly, and energy-saving. ceramic heating element, which is mainly used to replace the most widely used alloy wire heating elements and PTC heating elements and components.

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Alumina Ceramic Heater

Related Searches

- Resistance heater

- Tubular resistance heater

- Cartridge heater

- Flat resistance heater

- Ceramic resistance heater

- Flexible resistance heater

- Industrial resistance heater

- PTC resistance heater

- Compact resistance heater

- Tubular cartridge heater

- Custom resistance heater

- Igniter

- 230 V cartridge heater

- Plate heating element

- Round heating element

- Automotive heating element

- High-temperature cartridge heater

- Burner igniter

- Heating element for medical applications

- Liquids and gase heating element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.