- Materials - Tools - Components

- Standard Mechanical Component

- Xiamen Innovacera Advanced Materials Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

Ceramic ring precisionfor pad printing

Add to favorites

Compare this product

Characteristics

- Type

- precision

- Applications

- for pad printing

- Material

- ceramic

Description

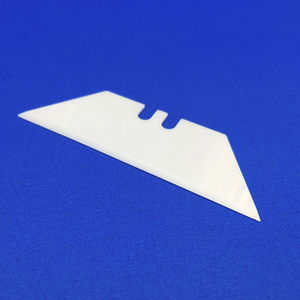

In the contemporary industrial realm, pad printing technology finds extensive application across diverse surfaces, such as plastic, metal, glass, and ceramics. With the escalating demand for high-quality and durable prints, traditional pad printing rings frequently fail to fulfill the exacting printing requirements. Nevertheless, zirconia pad printing rings have emerged as the preeminent solution, presenting remarkable performance and durability.

What Are Zirconia Pad Printing Rings?

Zirconia represents an advanced ceramic material renowned for its extraordinary hardness, corrosion resistance, and wear resistance. Zirconia pad printing rings are fabricated using this robust material, thereby constituting essential components within pad printing systems that necessitate outstanding durability and precision.

What Are Zirconia Pad Printing Rings?

Zirconia is an advanced ceramic material known for its exceptional hardness, corrosion resistance, and wear resistance. Zirconia pad printing rings are manufactured using this robust material, making them essential components in pad printing systems that require outstanding durability and precision.

Advantages of Zirconia Pad Printing Rings:

1.Superior Wear Resistance

The elevated hardness of zirconia confers significantly enhanced wear resistance in comparison to conventional metal or plastic materials. Even during prolonged and high-frequency printing operations, zirconia rings manifest minimal wear, leading to an extended service life and diminished maintenance requirements.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xiamen Innovacera Advanced Materials Co., Ltd‘s catalogsOther Xiamen Innovacera Advanced Materials Co., Ltd products

Zirconia Ceramic

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.