- Detection - Measurement

- Flow, Pressure and Level Measurements

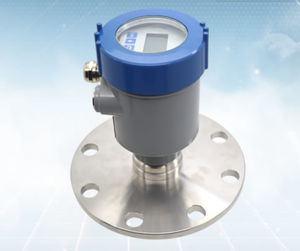

- Radar level transmitter

- Xian Kacise Optronics Co., Ltd.

Radar level transmitter KLD802liquidRS-485HART

Add to favorites

Compare this product

Characteristics

- Technology

- radar

- Medium

- liquid

- Interface

- 4-20 mA, HART, RS-485, CAN

- Other characteristics

- maintenance-free, IP67

- Level range

Max.: 100 m

(328'01" )Min.: 0.1 m

(0'03" )- Process pressure

Max.: 1.6 MPa

Min.: -0.1 MPa

- Process temperature

Max.: 110 °C

(230 °F)Min.: -40 °C

(-40 °F)

Description

KLD802 Maintenance-free Radar Level Sensor with Non-contact PTFE Lens Antenna for Continuous Level Measurement

Introduction

The 80G radar level sensor adopts frequency modulated continuous wave (FMCW) technology, and transmits a high frequency continuous frequency modulated radar signal through its antenna. The transmitted signal is reflected by the medium and received by the antenna as echoes with different frequencies. The change in frequency is proportional to the distance and converted to material level height.

KLD800 series 80G ultra-high frequency radar instrument uses a non-contact measurement method to measure the level of liquid and solid media. They measure a wide variety of liquid media, even at high pressures and extreme temperatures. Such as solvent measurement, corrosive medium measurement, hygienic measurement, etc. At the same time, it can also measure light and heavy solids stably and reliably. Even strong dust and noise, adhesion and condensation will not affect the measurement results.

Feature

1. Non-contact measurement.

The measurement will not be affected by changes in medium properties or process conditions, such as temperature, pressure or dust intensity. Adjusting settings is easy, eliminating the need for filling and emptying containers, saving time during instrument start-up, and making the instrument virtually maintenance-free.

2. Large measuring range and small blind area

The measurement range is 0.1~120m, which basically meets the measurement requirements of on-site working conditions.

Other Xian Kacise Optronics Co., Ltd. products

Radar Level Transmitter

Related Searches

- Flowmeter

- Volume flowmeter

- Liquid flowmeter

- Pressure transmitter

- Pressure gauge

- Level limit switch

- Level probe

- Liquid level limit switch

- Analog pressure transmitter

- Liquid level probe

- Gas flowmeter

- Stainless steel flowmeter

- Analog pressure indicator

- Waterproof flowmeter

- Pressure switch

- Pressure probe

- Industrial flowmeter

- Waterproof pressure transmitter

- Stainless steel pressure transmitter

- Membrane pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.