- Detection - Measurement

- Flow, Pressure and Level Measurements

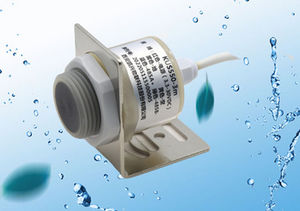

- Radar level sensor

- Xian Kacise Optronics Co., Ltd.

Radar level sensor 36720230liquidRS-485HART

Add to favorites

Compare this product

Characteristics

- Technology

- radar

- Medium

- liquid

- Interface

- 4-20 mA, HART, Modbus, RS-485

- Other characteristics

- IP67

- Level range

Max.: 100 m

(328'01" )Min.: 0.1 m

(0'03" )- Process pressure

Max.: 2.5 MPa

Min.: -0.1 MPa

- Process temperature

Max.: 200 °C

(392 °F)Min.: -40 °C

(-40 °F)

Description

The Difference In Application Of Radar Level Transmitter Frequency Range

Dirty and polluted environment

With long-term use, dirt and pollutants accumulated on the antenna will affect the strength and direction of the radar signal. For high frequency signals, any dirt that covers the antenna will absorb more energy, and the direction of the beam may change. This results in a loss of signal strength. So, low-frequency and medium-frequency technologies are more suitable.

Storage tanks with condensate and/or steam

Condensation and steam can cause reflections on product surfaces to be masked by the “noise” of water droplets. This is more of a problem for high frequency signals. So mid and low frequency techniques are a better choice. Antennas with flat, horizontal surfaces should always be avoided for condensation.

High steam and agitation

Be sure to choose the 80G millimeter-wave radar level meter. The 80G radar level meter has a high transmission frequency and has good penetration and is not affected by steam. The 2° transmission angle can effectively avoid the interference of the stirring blade. The unique echo Tracking algorithm avoids reading multiple echoes when the material level is high.

Applications with turbulence, waves and ripples

Waves and ripples are often found on the surface of process liquids in large tanks. And this turbulence is especially detrimental to high-frequency measurements. Low and mid frequency level instruments emit longer wavelengths, making them perform better.

Foam application

Like dust and condensation, a layer of foam on top of the liquid can absorb the radar signal, making accurate measurements more difficult.

Other Xian Kacise Optronics Co., Ltd. products

Fluid Level Meter

Related Searches

- Flowmeter

- Liquid flowmeter

- Pressure transmitter

- Level limit switch

- Pressure gauge

- Level probe

- Liquid level limit switch

- Analog pressure transmitter

- Liquid level probe

- Gas flowmeter

- Stainless steel flowmeter

- Analog pressure indicator

- Pressure switch

- Waterproof flowmeter

- Pressure probe

- Industrial flowmeter

- Relative pressure transmitter

- Membrane pressure transmitter

- Waterproof pressure transmitter

- Stainless steel pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.