- Detection - Measurement

- Flow, Pressure and Level Measurements

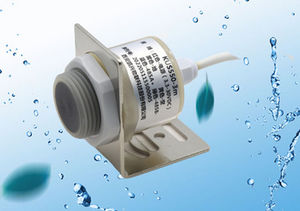

- Radar level transmitter

- Xian Kacise Optronics Co., Ltd.

Radar level transmitter 36722848for liquids4-20 mARS-485

Add to favorites

Compare this product

Characteristics

- Technology

- radar

- Medium

- for liquids

- Interface

- 4-20 mA, RS-485, CAN, wireless

- Level range

Min.: 0.1 m

(0'03" )Max.: 100 m

(328'01" )- Process pressure

Min.: -0.1 MPa

Max.: 1 MPa

- Process temperature

Min.: -40 °C

(-40 °F)Max.: 130 °C

(266 °F)

Description

In the process of industrial automation control, material level is an important parameter. There are many methods of material level measurement. For different working conditions and media, material level gauges with different measurement principles can be used for measurement, such as static pressure type, float type, heavy hammer type, ultrasonic and other common material level measurement methods. Instruments have their own characteristics and application ranges. Radar level gauge uses advanced radar pulse wave measurement technology, with its excellent performance, especially in tanks with agitation, high temperature, large steam, strong dust, strong medium corrosion, easy scarring and other harsh measurement conditions It shows its excellent performance and plays an important role in industrial automation production.

Wireless Radar System Solutions:

In the production process of petrochemical, coal, cement, metallurgy and other industries, in order to ensure the safety of liquid during storage, real-time monitoring of pressure, liquid level, temperature, humidity and gas concentration on the liquid surface in the storage tank, etc. How to collect and transmit the relevant parameters of the liquid stored in the storage tank to the remote control center, and how to initiate emergency measures in case of emergency has always troubled the management personnel. Traditional storage tank monitoring mainly relies on periodic inspections by personnel on duty. The labor cost is high, and many human factors will be left behind, posing safety risks.

Other Xian Kacise Optronics Co., Ltd. products

Fluid Level Meter

Related Searches

- Flowmeter

- Liquid flowmeter

- Pressure transmitter

- Level limit switch

- Pressure gauge

- Level probe

- Liquid level limit switch

- Analog pressure transmitter

- Liquid level probe

- Gas flowmeter

- Stainless steel flowmeter

- Analog pressure indicator

- Pressure switch

- Waterproof flowmeter

- Pressure probe

- Industrial flowmeter

- Relative pressure transmitter

- Membrane pressure transmitter

- Waterproof pressure transmitter

- Stainless steel pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.