- Detection - Measurement

- Flow, Pressure and Level Measurements

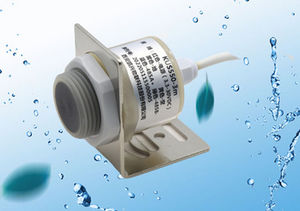

- Radar level sensor

- Xian Kacise Optronics Co., Ltd.

Radar level sensor 36720434for liquidsRS-485HART

Add to favorites

Compare this product

Characteristics

- Technology

- radar

- Medium

- for liquids

- Interface

- 4-20 mA, HART, Modbus, RS-485, CAN, wireless

- Level range

Max.: 100 m

(328'01" )Min.: 0.3 m

(0'11" )- Process pressure

Max.: 0.3 MPa

Min.: -0.1 MPa

- Process temperature

Max.: 110 °C

(230 °F)Min.: -40 °C

(-40 °F)

Description

Flour Radar Level Sensor With Purge Function Apply In Strong Dust Application

Introduction

Technology for Silo Level Measurement

The state of the agriculture industry and the scale of operations in today’s market has demanded more effective tools for grain management. Where a silo level monitoring system of the past could have used manual or mechanical methods to determine grain levels, many of the silos used today are massive, making these systems highly impractical.Today, silo-level radar is a popular method for designing an efficient bin-level measurement tool. Silo radar level measurement uses a pulse generator and a grain bin fill sensor to determine the level of solids present in the silo. The pulse is transmitted down a contact cable or rod, then returns when it encounters the change in dielectric marked by the shift from air to the grain. The system then calculates the travel time of the pulse to determine the grain silo level measurement.Another method of wireless bin monitoring employs ultrasonic sensors to launch and receive a mechanical pulse that detects a level-based density change. These systems are relatively small and tend to be highly cost-effective. However, since sound waves are affected by both moisture and ambient temperature, ultrasonic bin level monitors are not ideal for humid environments or those prone to significant temperature fluctuation.A more robust solution, laser silo level sensors require no contact and can accurately detect grain levels at a long-range.

Other Xian Kacise Optronics Co., Ltd. products

Fluid Level Meter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.