- Production Machines

- Other Manufacturing Equipment

- Roller mill

- Xinxiang Great Wall Machinery Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Roller grinding mill mill grinding tablediscverticalfor powders

Add to favorites

Compare this product

Characteristics

- Technology

- roller, disc

- Orientation

- vertical

- Product applications

- for powders, for limestone, stone

Description

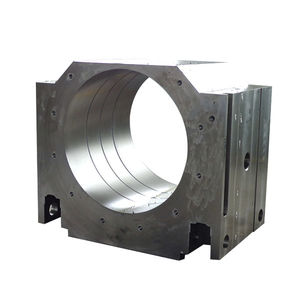

The grinding table is key part of the vertical roller mill. The primary function of the grinding table is to support the material bed and transfer the force of the grinding roller to the lower speed reducer. It also transmits the torque of the reducer to the grinding area.

CHAENG is able to make all kinds of grinding tables for vertical mill according to the drawings and sizes provided by the customers. Welcome to visit and consult!

Weight: 20-132 t

Material: Carbon steel, silicon manganese steel

Application equipment: Vertical roller mill

Processing advantages

1. Optimize the casting technology of grinding table and adopt advanced water glass sand modeling process to overcome the shortcomings of the previous structure, so that the grinding table base bears stress evenly; Increase the nip angle between grinding table and grinding rollers to avoid the erosion of the non wearing surface of grinding table.

2. Advanced machining equipment to ensure high surface finish of grinding table.

3. Nondestructive inspection of the stress surface before leaving the factory can ensure that the internal and external quality of the grinding table conforms to the industry standards.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xinxiang Great Wall Machinery Co., Ltd‘s catalogsOther Xinxiang Great Wall Machinery Co., Ltd products

Steel Casting

Related Searches

- Grinding mill

- Horizontal grinding mill

- Vertical grinding mill

- Waste lump breaker

- Roller grinding mill

- Building materials grinding mill

- Recycling grinding mill

- Stainless steel grinding mill

- Mineral mill

- Powder grinding mill

- Dry milling grinding mill

- Rotary drum grinding mill

- Ball grinding mill

- Disc pulverizer

- Stone grinding mill

- Ore grinding mill

- Coal grinding grinding mill

- Large grinding mill

- Limestone grinding mill

- Cement grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.