- Production Machines

- Other Manufacturing Equipment

- Vertical roller mill

- Xinxiang Great Wall Machinery Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Vertical roller grinding mill mill grinding rollerverticalfor powdersstone

Add to favorites

Compare this product

Characteristics

- Technology

- vertical roller

- Orientation

- vertical

- Product applications

- for powders, stone

Description

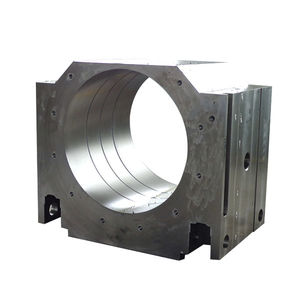

Grinding roller is key part of the vertical roller mill, CHAENG can make all kinds of Grinding roller for vertical mill according to the drawings and sizes provided by the customers.

Material: ZG30Mn, etc

Weight: 20-120t

Application: vertical roller mill

Customizable: Yes, according to customer's drawings

According to customer requirements, CHAENG select the appropriate wooden mold for modeling design, use CAE simulation casting before actual casting, in strict accordance with the technological process of wooden mold – modeling – smelting pouring – heat preservation –sand cleaning and out of the pit – heat treatment – rough machining and fine machining – packaging and delivery, cast supporting roller with high quality.

1. The grinding roller of CHAENG (Great Wall machinery) adopts ZG30mn as casting material, with high hardness, anti-cracking and good wear resistance.

2. During production, CHAENG adopts arc air gouging to make the finishing treatment of the grinding roller, so as to ensure the appearance quality of the cast steel.

3. The unique design of CHAENG makes it with low wear during operation, and makes the maintenance quantity and replacement quantity greatly reduced, and the service life is longer.

4. Before leaving the factory, check the stress surface through the testing method of the process, ensure the quality of every grinding roller is reliable, and eliminate inferior products and defective products from the factory.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Xinxiang Great Wall Machinery Co., Ltd‘s catalogsOther Xinxiang Great Wall Machinery Co., Ltd products

Steel Casting

Related Searches

- Grinding mill

- Horizontal grinding mill

- Vertical grinding mill

- Waste lump breaker

- Roller grinding mill

- Building materials grinding mill

- Recycling grinding mill

- Stainless steel grinding mill

- Mineral mill

- Dry milling grinding mill

- Powder grinding mill

- Rotary drum grinding mill

- Ball grinding mill

- Disc pulverizer

- Stone grinding mill

- Ore grinding mill

- Coal grinding grinding mill

- Large grinding mill

- Limestone grinding mill

- Cement grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.