- Products

- Girth gear for the steel industry

- Xinxiang Great Wall Machinery Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

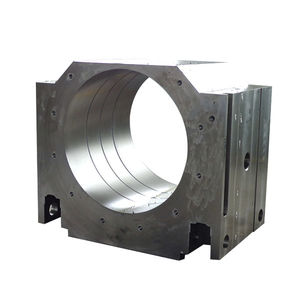

Ball mill girth gear Customized girth gearfor the cement industryfor the steel industry

Add to favorites

Compare this product

Characteristics

- Applications

- for ball mills, for the cement industry, for the steel industry

- Diameter

Min.: 2 m

(6'06" )Max.: 12 m

(39'04" )

Description

Girth gear is an important transmission part of rotary kiln and ball mill equipment. The motor drives the pinion and pinion drives the girth gear mounted on the cylinder shell, because of this, the ball mill start driving. The girth gear is connected to the cylinder shell by bolt.

CHAENG can produce all kinds of large gear ring according to the drawings and sizes provided by customers.

Weight:10-80 t

Materials: ZG45, ZG42CrMO

Customized: Yes, according to customers' drawings

1. High abrasion resistance

The CHAENG adopts unique heat treatment technology in casting, which optimizes the gear’s structure, improves its hardness, and greatly enhances its wear resistance and the impact force.

2. High strength steel ensures, long working time

The CHAENG uses the high-strength steel for gear casting, and optimize it according to the transmission characteristics of rotary kiln, ball mill which ensure its stability during long-time working and prolong the service life of the components.

3. Efficient mass production, shorten the delivery time

CHAENG has strong strength for steel casting parts, and can produce in large quantities with short production time and high output.

VIDEO

Catalogs

Other Xinxiang Great Wall Machinery Co., Ltd products

Steel Casting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.