- Materials - Tools - Components

- Standard Mechanical Component

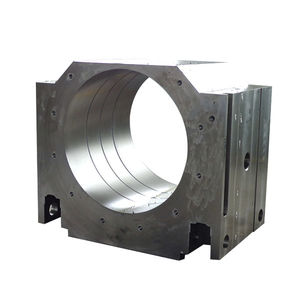

- Load support

- Xinxiang Great Wall Machinery Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Load support Rotary kiln support rollerroller

Add to favorites

Compare this product

Characteristics

- Applications

- load

- Other characteristics

- roller

Description

The supporting roller is one of the main parts of the rotary kiln, which partly support the weight of the rotary kiln and allows the cylinder and tire to rotate smoothly on the support roller. Therefore, the supporting roller with ultra-endurance becomes one criteria of measuring quality of the rotary kiln.

CHAENG can provide variety of rotary kiln parts casting and processing service as per the drawing of customers.

Weight:1-42t

Material:ZG55, ZG42CrMo

Customized:Yes, according to customer' drawings

Product advantages

CHAENG has one of the few large foundry bases in the same industry, with an annual output of 50,000 tons, especially in the casting of cement plant equipment parts such as supporting roller, which has obvious advantages:

1. The supporting roller has large load and continuous operation.

The supporting roller of CHAENG are usually made of ZG55, ZG42CrMo and other materials, which ensure the quality of the roller, and on the other hand, it has the advantages of large load and continuous running.

2. Simple structure, easy to adjust& maintenance

The supporting roller uses the rolling bearing group with characteristics of simple structure and convenient maintenance.

3. Strict control of heat treatment . high hardness of products

CHAENG adopts normalizing and tempering procession in the roller casting, and finally the surface hardness of the outside circle is higher than 200HB, which guarantees the quality of supporting roller of the rotary kiln.

VIDEO

Catalogs

Kiln supporting roller

1 Pages

Other Xinxiang Great Wall Machinery Co., Ltd products

Steel Casting

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.