- Industrial machines and equipment

- Furnace and Heat Treatments

- Pit oven

- Xinxiang Great Wall Machinery Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

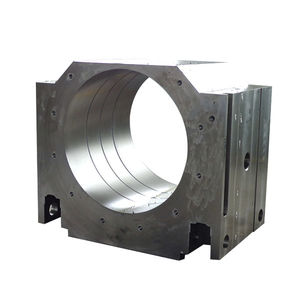

Chamber furnace SLAG POTpitmeltingfor metallurgy

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber, pit

- Function

- melting

- Other characteristics

- for metallurgy

Description

Slag pot is also called casting ladle, slag bucket, or slag ladle. It is important container holding high temperature liquid steel slag in the process of steel making.

With richly experience and advanced casting equipment, CHAENG has the capability to offer slag pots (slag ladles) in nearly every shape and style for a variety of mounting systems and transport methods, according to customers’ drawings, utilized in BOFs, AODs, Electric Arc and Blast Furnaces, and so on, suited for a number of processes, such as lead, aluminium, iron, steel, chrome, manganese, copper and other smelting applications.

Weight: 10-85 t

Material: ZG230-450 plus RE etc.

Customizable: Yes

Reliable product quality

1.Select proper materials and optimize the casting processes of slag pot, according to customers’ actual operation conditions and actual demands.

2.Digital simulation for casting process through CAE software, to optimize the slag pot casting process.

3.Longer service life, 6000 times of usage frequency.

4.Excellent high-temperature mechanical properties, good thermal cracking resistance.

5.First maintenance can be done 2~3 months later than similar products from other manufacturers.

6.Level 2 of flaw detection - Ultrasonic and magnetic particle flaw detection level can reach the second level of national standards.

7.Smooth inner wall of slag pot, to avoid adhering slag during operation.

VIDEO

Catalogs

Other Xinxiang Great Wall Machinery Co., Ltd products

Steel Casting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.