- Products

- Catalogs

- News & Trends

- Exhibitions

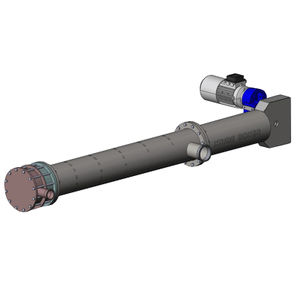

Tube-tube heat exchanger XLG® Sliquid/liquidstainless steelindustrial

Add to favorites

Compare this product

Characteristics

- Type

- tube-tube

- Fluid

- liquid/liquid

- Material

- stainless steel

- Applications

- industrial

Description

These are corrugated tube heat exchangers formed by two concentric tubes and are especially useful for treating slurries (fluids which contain significant amounts of fibres or suspended particles) and particulate fluids (such as fruit dices).

Characteristics

XLG®S Tube-in-Tube heat exchangers are constructed from stainless steel and are formed by having two concentric tubes. The fluid to be treated is normally passed through the corrugated inner tube and the service fluid, providing the source of cooling or heating, passes through the annulus formed by the two tubes.

This range is formed from units of different tube diameters chosen according to the flow rates of the working fluids. Corrugated tubes are used in order to significantly enhance the rate of heat transfer and thus minimise the size of heat exchanger required.

Materials of construction

All product wetted components (interior tube and bends etc.) are manufactured from AISI 316L stainless steel but for more aggressive fluids a range of Duplex stainless steels are also available.

The service side components are normally made from AISI 304 stainless steel but AISI 316L and Duplex steels may be used when required.

Areas not in contact with the working fluids are normally constructed from AISI 304 stainless steel.

Silicone rubber is normally used for the O ring seals and connection gaskets or seals but a wide range of alternative elastomers are available when specific applications require them.

Alternative materials can be offered for all wetted components on application.

Related Searches

- Heat exchanger unit

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Tubular heat exchanger

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Industrial heat exchanger unit

- Shell and tube heat exchanger

- Heat exchanger for the food industry

- Titanium heat exchanger

- Pressure heat exchanger

- Nickel heat exchanger

- Heat exchanger for the pharmaceutical industry

- High-pressure heat exchanger

- High-temperature heat exchanger

- Sanitary heat exchanger

- Scraped surface heat exchanger

- Multi-tube heat exchanger

- Viscous product heat exchanger

- Tube-tube heat exchanger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.