- Products

- Catalogs

- News & Trends

- Exhibitions

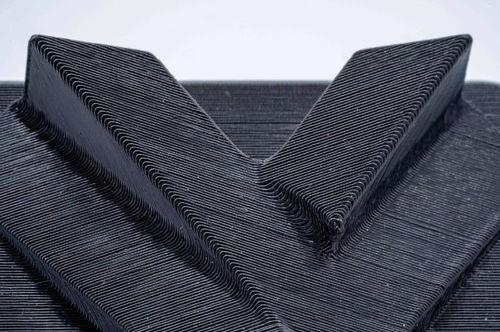

Plastic 3D printing FDMfor the electronics industryfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- plastic

- Technology

- FDM

- Applications

- prototyping, medical, for the aerospace industry, for the automotive industry, for the electronics industry

Description

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its great material selection, accuracy, possibility to print large parts, and competitive cost. FDM parts are great for end-use, low-volume production, for rapid prototyping. FDM 3D prints usually do not require any post-processing.

Try Xometry Out Now In Just A Few Steps

Upload your CAD files

1

Multiple designs for different parts can be imported at the same time to produce a single quote. In less than a minute, a detailed cost estimation appears on the screen.

Choose the process

2

First, select the manufacturing process you require. You can then choose from over 70 materials, both metals and plastics, and from a wide range of finishes and certifications.

Order your parts online

3

Once you have selected the required options, all you need to do is confirm the order and pay for it on the secure payment platform. Your design will be analysed by engineers.

Advantages of FDM with Xometry

Massive Capacity

We can quickly produce both prototypes and large batches thanks to the largest manufacturing network in Europe, with over 2,000 vetted partners

Fast Production

You will get your 3D printed parts fast delivered in as fast as 8 days.

Quality Assurance

We have strong QA procedures, controlled by an in-house team of QA engineers, which allows us to deliver high quality parts.

Engineering Check & Status Updates

All designs are checked by engineers before they’re sent for 3D printing. After confirming your order, you will receive status updates on your production.

Catalogs

No catalogs are available for this product.

See all of Xometry Europe‘s catalogsRelated Searches

- Plastic injection molding

- Thermoplastic plastic injection molding

- 3D printing

- Plastic 3D printing

- Industrial 3D printing

- Prototyping 3D printing

- Injection molding for the electronics industry

- Medical injection molding

- Injection molding for the automotive industry

- Prototyping plastic injection molding

- Medical 3D printing

- FDM 3D printing

- 3D printing for the automotive industry

- 3D printing for the aerospace industry

- Bi-material plastic injection molding

- 3D printing for the electronics industry

- Rubber injection molding

- SLA 3D printing

- DMLS 3D printing

- Multi jet fusion 3D printing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.