- Power Transmission - Mechanical components

- Mechanical Transmission

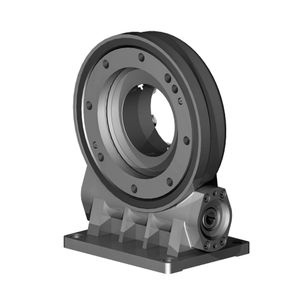

- Slewing ring slewing drive

- XUZHOU FENGHE SLEWING BEARING CO.,LTD

Slewing ring slewing drive singleworm geardouble

Add to favorites

Compare this product

Characteristics

- Options

- worm gear, slewing ring, single, double

- Applications

- for solar trackers, for wind turbine, for crane

- Other characteristics

- custom-made, heavy-duty, high load capacity, high-torque

- Torque

Min.: 400 Nm

(295.0249 ft.lb)Max.: 18,000 Nm

(13,276.1187 ft.lb)- Gear ratio

Min.: 62 unit

Max.: 150 unit

Description

The worm-gear type slewing drive is developed by the slewing bearing. It is composed of housing, a turbine ferrule, a worm gear, a motor and kits. Compared with the conventional slewing bearing, the structure is compacted, safe and modularity. The characteristics of modify the main engine. Nowadays, due to the demand for heavy loading, the duplex worm slew drive device has been developed. It has better product structure compactness and high loading ability and higher output torque.

Slew drive can be widely used for 360° rotating and speed shifting, large torque smoothly transmission, high precision matching or compacted mechanism is mostly relied on slew drive, for its special solution and widely application below:

Heavy loading gantry crane

The slewing drive has changed the traditional mode of heavy loading gantry cranes in this field, greatly reducing operating costs and maintenance costs, it has been adopted by more and more host manufacturers by its effective.

Aerial work vehicle field

The slewing bearing motivates slewing drive which has developed rapidly and has obvious advantages in this field.

Heavy loading flatbed truck (beam truck)

Due to the heavy load, duplex worm slew drive are widely used for providing a large output torque.

Port cranes

While using a slew drive to fulfill the loading moment, the conventional hydraulic cylinder is another way to modify the rotating of slewing ring.

New energy field

With the support of national policies, the prospects of the rotary drive in this field are very impressive.

VIDEO

Catalogs

No catalogs are available for this product.

See all of XUZHOU FENGHE SLEWING BEARING CO.,LTD‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other XUZHOU FENGHE SLEWING BEARING CO.,LTD products

Slewing drive

Related Searches

- FENGHE slewing drive

- FENGHE solar tracker slewing drive

- FENGHE compact slewing drive

- FENGHE slewing ring slewing drive

- FENGHE single slewing drive

- FENGHE custom-made slewing drive

- Dust-proof slewing drive

- FENGHE double slewing drive

- FENGHE wind turbine slewing drive

- FENGHE satellite dish slewing drive

- Crane slewing drive

- Hydraulic drive slewing drive

- FENGHE straight-toothed slewing drive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.