- Power Transmission - Mechanical components

- Mechanical Transmission

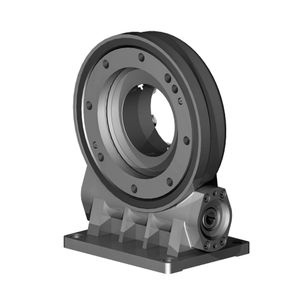

- Straight-toothed slewing drive

- XUZHOU FENGHE SLEWING BEARING CO.,LTD

Straight-toothed slewing drive VE5singledual-axisfor wind turbine

Add to favorites

Compare this product

Characteristics

- Options

- single, straight-toothed, dual-axis

- Applications

- for industrial automation, for satellite dishes, for wind turbine

- Other characteristics

- custom-made, heavy-duty, high load capacity

- Torque

Max.: 68,000 Nm

(50,154.2262 ft.lb)365 Nm

(269.2102 ft.lb)Min.: 500 Nm

(368.7811 ft.lb)- Gear ratio

Max.: 9,822 unit

668 unit

Min.: 350 unit

Description

The slewing bearing is the key load-bearing element, capable of handling radial, axial, and tilting moments. A worm gear mechanism is used to transmit the motor’s rotational motion to the slewing ring, providing high torque and a self-locking feature for enhanced safety. The electric motor powers the system, offering precise control over speed and position.

Precision and Control: Electric slewing drives allow for fine-tuned, accurate positioning, making them ideal for applications such as solar tracking systems, where the panels need to follow the sun’s movement for maximum energy efficiency.

Self-locking: The worm gear’s self-locking property ensures that the system remains in position even when power is off, providing additional safety, especially in critical applications like cranes.

Durability and Low Maintenance: Thanks to the sealed housing and robust materials, electric slewing drives are highly durable, requiring minimal maintenance and offering long service life.

VIDEO

Catalogs

VE5 Slew Drive catalog

1 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Other XUZHOU FENGHE SLEWING BEARING CO.,LTD products

Slewing drive

Related Searches

- FENGHE slewing drive

- FENGHE solar tracker slewing drive

- FENGHE compact slewing drive

- FENGHE slewing ring slewing drive

- FENGHE single slewing drive

- FENGHE custom-made slewing drive

- Dust-proof slewing drive

- FENGHE double slewing drive

- FENGHE wind turbine slewing drive

- FENGHE satellite dish slewing drive

- Crane slewing drive

- FENGHE straight-toothed slewing drive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.