- Power Transmission - Mechanical components

- Mechanical Transmission

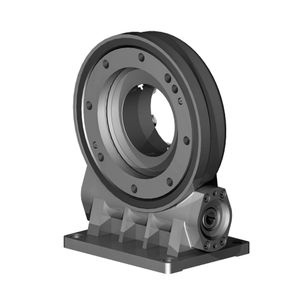

- Single slewing drive

- XUZHOU FENGHE SLEWING BEARING CO.,LTD

Custom-made slewing drive singleworm gearfor solar trackers

Add to favorites

Compare this product

Characteristics

- Options

- worm gear, single

- Applications

- for solar trackers, for satellite dishes

- Other characteristics

- compact, dust-proof, custom-made

- Torque

Min.: 4,800 Nm

(3,540.2983 ft.lb)Max.: 68,000 Nm

(50,154.2262 ft.lb)- Gear ratio

Min.: 55 unit

Max.: 80 unit

Description

When considering slewing drives, choosing between custom or standard designs depends on your specific application needs.

Custom Design:

Tailored Solutions: Designed to meet unique specifications, ensuring optimal performance for specialized applications.

Enhanced Performance: Can integrate specific features or modifications that standard designs may not accommodate, improving efficiency and longevity.

Flexibility: Allows for adjustments in size, torque, and mounting options based on operational requirements.

Standard Design:

Cost-Effective: Generally less expensive due to mass production and reduced engineering costs.

Quick Availability: Standard models are readily available, facilitating faster project timelines.

Proven Reliability: Tested designs with established performance metrics in various applications, offering peace of mind.

Ultimately, if your project has unique requirements or challenges, a custom slewing drive may be the best choice. However, for more common applications, standard designs can provide a reliable and efficient solution.

VIDEO

Catalogs

No catalogs are available for this product.

See all of XUZHOU FENGHE SLEWING BEARING CO.,LTD‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other XUZHOU FENGHE SLEWING BEARING CO.,LTD products

Slewing drive

Related Searches

- FENGHE slewing drive

- FENGHE solar tracker slewing drive

- FENGHE compact slewing drive

- FENGHE slewing ring slewing drive

- FENGHE single slewing drive

- FENGHE custom-made slewing drive

- Dust-proof slewing drive

- FENGHE double slewing drive

- FENGHE wind turbine slewing drive

- FENGHE satellite dish slewing drive

- Crane slewing drive

- Hydraulic drive slewing drive

- FENGHE straight-toothed slewing drive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.