- Electricity - Electronics

- Cable, Connector, Enclosure

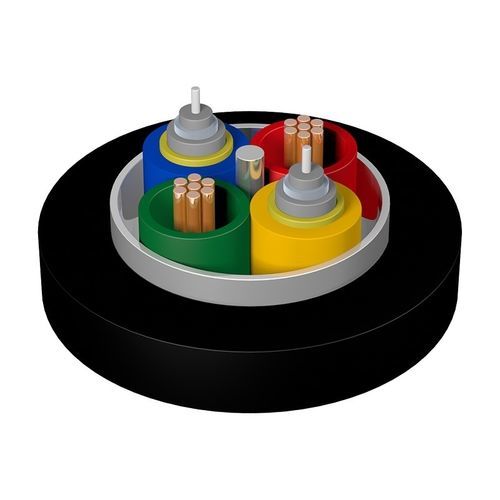

- Hybrid optical cable

- Yangtze Optical Fibre and Cable Joint Stock Limited Company

Hybrid optical cable GDFKJHdatapowerarmored

Add to favorites

Compare this product

Characteristics

- Type

- data, power, hybrid

- Protection

- armored, water-resistant

- Configuration

- multi-fiber, stranded

- Core material

- copper, steel

- Applications

- for indoor use, distribution

- Material of the insulation

- aramid yarn

- Other characteristics

- flexible, buffered

- Temperature

Min.: -20 °C

(-4 °F)Max.: 60 °C

(140 °F)

Description

Tight buffered fibres are surrounded with a helical steel hose and a layer of aramid yarns as the strength member, and then a LSZH sheath is extruded to form an optical sub-unit. Optical sub-units and copper wires are stranded around a non-metallic central strength member to form a cable core. The core is wrapped with water blocking tape. Finally, a LSZH outer sheath is extruded. Other sheath materials are available on request.

• Good mechanical and temperature performances

• Stainless steel hose armor providing better protection to fibres

• Good crush resistance and flexibility

• All-dry hybrid structure, supporting bulk data transmission and power supply for RRU devices

• Mainly applied to local fibre remote for short distance at wireless base stations, applicable to the construction of indoor distributed base stations

• Standard length: 1,000m; other lengths are also available.

Catalogs

No catalogs are available for this product.

See all of Yangtze Optical Fibre and Cable Joint Stock Limited Company‘s catalogsOther Yangtze Optical Fibre and Cable Joint Stock Limited Company products

Cable Product

Related Searches

- Electrical connector

- Electrical cable

- Data electrical connector

- Rectangular box

- Copper cable

- Copper electrical cable

- Power cable

- Plastic box

- Insulated cable

- Wall-mounted enclosure

- Multi-strand cable

- Insulated electrical cable

- Terminal box

- Flexible cable

- Optical cable

- Wall-mounted terminal box

- Industrial cable

- Cable assembly

- Protection box

- Optical data cable

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.