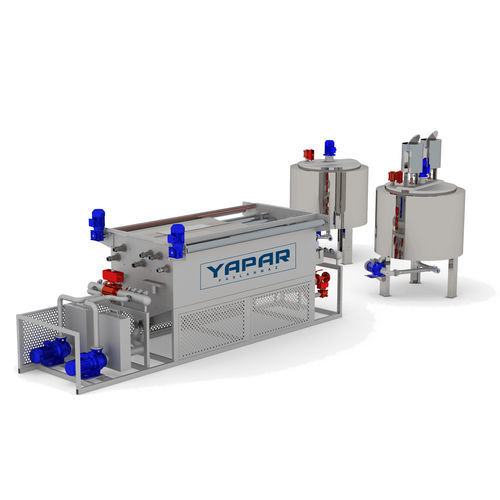

Water washing machine NIL EVOLUTIONprocessfor the textile industryenvironmentally friendly

Add to favorites

Compare this product

Characteristics

- Technology

- water

- Applications

- process, for the textile industry

- Other characteristics

- environmentally friendly, ecological

- Capacity

400 l

(105.67 gal)

Description

This machine designed for rough cleaning of textile surfaces made of synthetic or natural materials.

It also enables to treat the selected textile surface with the desired chemicals, in the desired amount, in the desired degree continuously.

NIL EVOLUTION saves twice as much water as its counterparts through moving nozzles. The NIL EVOLUTON, which has low energy consumption, is 100% environmentally friendly.

As a basic principle, the selected textile surface at the entrance of the machine pulverize the solution in the machine provides the influence on the selected textile surface.

NIL EVOLUTION new generation ram pre washing machine

This machine designed for rough cleaning of textile surfaces made of synthetic or natural materials. It also enables to treat the selected textile surface with the desired chemicals, in the desired amount, in the desired degree continuously.

At the entrance of the machine, pulverize the solution in the machine to ensure the penetration of the selected textile surface.

In addition, it provides the penetration of the solution with the selected textile surface in the vessel, the cleaning of the selected textile surface in the vessel, and the transmission of the selected textile surface to the ram machine.

Main purposes of the Nil Evolution :

During the fixe process of lycra cotton fabrics, it is possible to remove the high degree of yarn and oil, wax, particulate, knitting oil… etc. from the flash bleaching process before the fixe process. In this way, both ecologically preventing the ejection of burnt oil from the Ramous exhaust system and Ramous chimney fires are minimized.

Catalogs

No catalogs are available for this product.

See all of YAPAR MAKİNA A.Ş‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.