- Machine-tools

- Machining Center

- 3-axis machining center

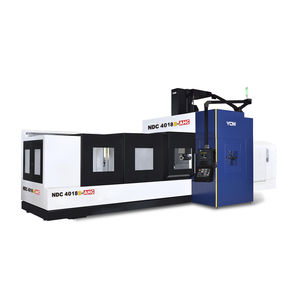

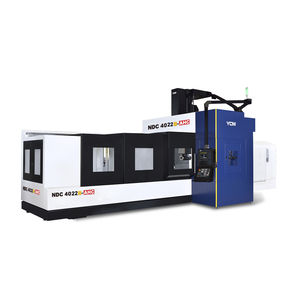

- YCM (Yeong Chin)

3-axis CNC machining center FP100Averticalgantrydouble-column

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- gantry, double-column

- Spindle mount

- BBT40

- Number of tool stations

- 24 tools

- Associated functions

- cutting

- Other characteristics

- high-speed, high-performance, high-precision, high-rigidity, direct-drive

- X travel

1,020 mm

(40.16 in)- Y travel

710 mm

(27.95 in)- Z travel

460 mm

(18.11 in)- Rotational speed

16,000 rpm, 20,000 rpm

(100,531 rad.min-1, 125,664 rad.min-1)- Power

22 kW, 37 kW

(29.91 hp, 50.31 hp)- Work feed X-axis

20,000 mm/min

(13 in/s)- Work feed Y-axis

20,000 mm/min

(13 in/s)- Work feed Z-axis

20,000 mm/min

(13 in/s)- Table load capacity

1,000 kg

(2,205 lb)- Tool weight (max)

6 kg

(13.2 lb)- Weight

12,000 kg

(26,455.47 lb)

Description

The symmetrical box-headstock design assures cutting rigidity while Z-axis is moving rapidly.

High rigidity high load precision ballscrews used and coupled with powerful servo axial motor, the Z-axis brake system sustains fine axial movement control, providing best dynamic accuracy and fine finish especially in the 3D micro-machining.

Fully supported worktable on the FEM analyzed machine base eliminates overhang with better accuracy.

The 4 million-pulse/rev high-resolution encoders in all axes achieve high precision status.

Automatic spindle cooling system effectively dissipates heat generated from long runtime through efficient oil cooling circulation.

Micro oil-air lubrication system consistently injects micro amount of lubricant to spindle bearings for maximizing spindle life.

Highly reliable helical disc spring design ensures optimal spindle balance.

Floating cylinder design for tool clamp/unclamp system eliminates unnecessary force on spindle bearings.

Perpetual pre-load design reduces the effect of spindle thermal growth under long spindle runtime.

Catalogs

Other YCM (Yeong Chin) products

Double Column Vertical Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.