- Machine-tools

- Machining Center

- 5-axis machining center

- YCM (Yeong Chin)

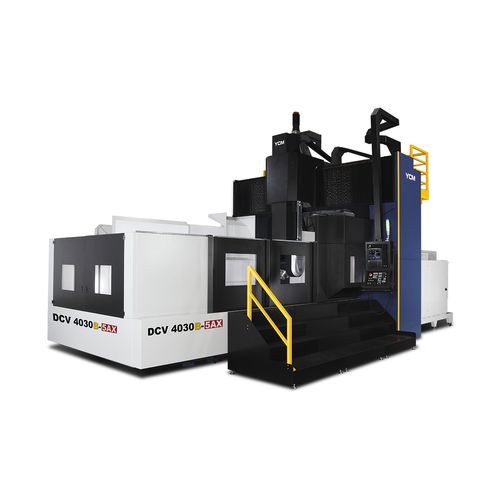

5-axis CNC machining center DCV4030B-5AXverticaldouble-columnHSK-100-A

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- double-column

- Spindle mount

- HSK-100-A

- Number of tool stations

- 40 tools, 120 tools

- Associated functions

- cutting

- Other characteristics

- high-precision, high-rigidity, direct-drive

- X travel

4,065 mm

(160.04 in)- Y travel

3,500 mm

(137.8 in)- Z travel

1,016 mm

(40 in)- Rotational speed

10,000 rpm

(62,832 rad.min-1)- Power

46 kW

(62.54 hp)- Work feed X-axis

20,000 mm/min

(13 in/s)- Work feed Y-axis

20,000 mm/min

(13 in/s)- Work feed Z-axis

15,000 mm/min

(10 in/s)- Table load capacity

20,000 kg

(44,092 lb)- Tool weight (max)

13 kg

(28.7 lb)- Weight

58,000 kg

(127,868.11 lb)

Description

5AX ROBO I Achieves Perfect 3D Contouring Operations

High rigidity symmetrical fork type structure design minimizes heat deformation during heavy cutting applications.

The main structure is made of superior nodular graphite cast iron.

Coolant through spindle system: 20 bar (opt.)

Superb spindle coolant system.

High Rigidity B/C Axis

HEIDENHAIN encoder enhances the cutting accuracy.

Disc type hydraulic clamping device.

Rotary joint design prevents the damage on the hydraulic tubes caused during rotation.

Double direction roller bearings for perfect cutting rigidity.

Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

Direct drive gearbox design on X/Y/Z axis offers smooth axial response, high torque, and low backlash.

Extra wide column base with boots design.

Equipped with roller type guideways and numerous slider blocks for great load capacity and cutting rigidity.

HEIDENHAIN Control

Program memory hard disk with 21 GB.

Tool center point management [TCPM]

Dynamic collision monitoring [DCM]

DXF converter (opt.)

Catalogs

Other YCM (Yeong Chin) products

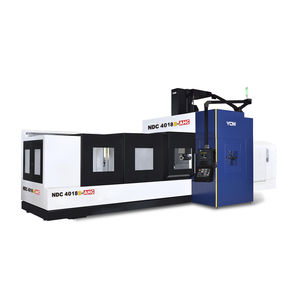

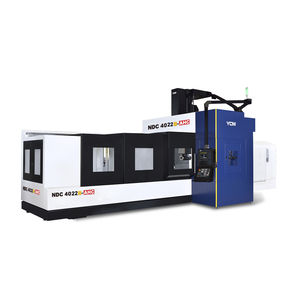

Double Column Vertical Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.