- Machine-tools

- Machining Center

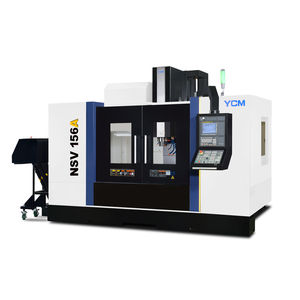

- 3-axis machining center

- YCM (Yeong Chin)

3-axis CNC machining center NSV106AverticalBBT4024 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- BBT40

- Number of tool stations

- 24 tools, 48 tools

- Associated functions

- tapping, cutting, drilling

- Other characteristics

- high-speed, high-precision, high-rigidity, with automatic tool changer

- X travel

1,020 mm

(40.16 in)- Y travel

600 mm

(23.62 in)- Z travel

600 mm

(23.62 in)- Rotational speed

12,000 rpm, 15,000 rpm

(75,398 rad.min-1, 94,248 rad.min-1)- Power

18.5 kW

(25.15 hp)- Work feed X-axis

48,000 mm/min

(31 in/s)- Work feed Y-axis

48,000 mm/min

(31 in/s)- Work feed Z-axis

32,000 mm/min

(21 in/s)- Table load capacity

700 kg

(1,543 lb)- Tool weight (max)

6 kg

(13.2 lb)- Tool-changing time

1.8 s

- Weight

7,000 kg

(15,432.36 lb)

Description

One-piece motor housing

Large delta machine column and base ensure the highest stability during high speed movement.

Advanced FEM analysis strengthens the structure while reduces the weight to provide the best cutting rigidity.

Y-axis guideway span with optimal ratio

The unique IDD spindle design offers smooth reliability at high speed.

Ceramic bearings do not just boost the spindle speed, but also achieve high axial and radial rigidity, which fulfill strict machining requirements on heavy cutting, drilling and tapping.

Efficient Chip Removal System

Equipped with triple-chip augers as a standard.

Dual-chip augers as an option.

Catalogs

No catalogs are available for this product.

See all of YCM (Yeong Chin)‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Cutting CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.