- Machine-tools

- Machining Center

- 5-axis machining center

- YCM (Yeong Chin)

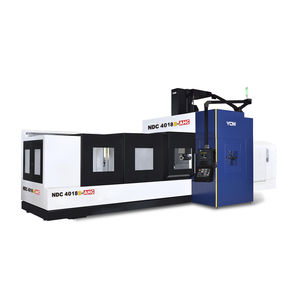

5-axis CNC machining center DCV4018A-5AXverticaldouble-columnHSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- double-column

- Spindle mount

- HSK A-63

- Number of tool stations

- 40 tools, 60 tools, 120 tools

- Other characteristics

- high-rigidity, direct-drive, with linear motor

- X travel

4,200 mm

(165.35 in)- Y travel

2,400 mm

(94.49 in)- Z travel

762 mm, 1,016 mm

(30 in, 40 in)- Rotational speed

18,000 rpm

(113,097 rad.min-1)- Power

56 kW, 70 kW

(76.14 hp, 95.17 hp)- Work feed X-axis

15,000 mm/min

(10 in/s)- Work feed Y-axis

24,000 mm/min

(16 in/s)- Work feed Z-axis

20,000 mm/min

(13 in/s)- Table load capacity

12,000 kg

(26,455 lb)- Tool weight (max)

6 kg

(13.2 lb)- Weight

36,000 kg

(79,366.41 lb)

Description

Reinforced Body Structure

One-piece Base

Ultimate rigidity and proportion of the headstock

Internal double A type ribbed bed design through FEM analysis offers full support for table.

1,800 mm distance between columns increases the stability of machine

Extra Rigidity Guideways

Y axis linear guideways design with large span with horizontal and vertical directions which can take the saddle weight and machining force.

X-axis is gearbox driven.

High Payload Table

The work table is precisely ground before assembled to ensure DCV series excellent machining results.

12 tons maximum table machining loading.

B/C-axis Head

B/C axis rotary speed 100 rev/min.

C-axis includes three roller bearings to increase rigidity and accuracy.

B-axis high rigidity and high accuracy cross roller bearing.

Heidenhain accuracy encoder included as standard.

Pneumatic positioning clamping equipment.

Over travel protection design.

B-axis anti-drop function at power outage.

Catalogs

No catalogs are available for this product.

See all of YCM (Yeong Chin)‘s catalogsOther YCM (Yeong Chin) products

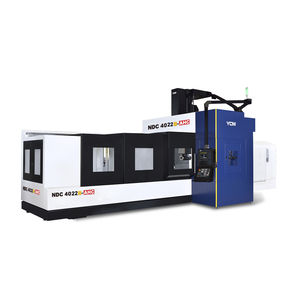

Double Column Vertical Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.