- Machine-tools

- Machining Center

- 3-axis machining center

- YCM (Yeong Chin)

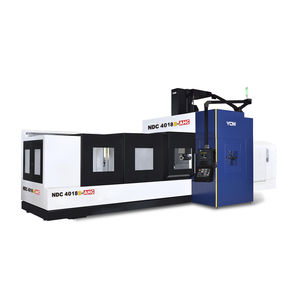

3-axis CNC machining center NDC4022B-AHCverticaldouble-column40 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- double-column

- Number of tool stations

- 40 tools, 60 tools

- Associated functions

- cutting

- Applications

- for heavy-duty machining

- Other characteristics

- high-precision, high-rigidity, direct-drive

- X travel

4,200 mm

(165.35 in)- Y travel

2,800 mm

(110.24 in)- Z travel

762 mm, 1,016 mm

(30 in, 40 in)- Rotational speed

6,000 rpm

(37,699 rad.min-1)- Power

35 kW

(47.59 hp)- Work feed X-axis

15,000 mm/min

(10 in/s)- Work feed Y-axis

15,000 mm/min

(10 in/s)- Work feed Z-axis

15,000 mm/min

(10 in/s)- Table load capacity

15,000 kg

(33,069 lb)- Tool weight (max)

20 kg

(44.1 lb)- Weight

39,000 kg

(85,980.28 lb)

Description

Reinforced Body Structure

Extra wide column base with boots design prevents the headstock from leaning forward.

Work table fully supported by base provides perfect dynamic accuracy.

X-axis adopts direct gear drive that provides high torque, high transmission efficiency and low backlash.

Z-axis head is boxway design that shows high rigidity and high damping, effectively avoids overhang, and vibration issues.

Wide span saddle enhances stabilization. With rigid beam and columns configuration, it provides Y-axis with the best straightness.

Y-axis and Z-axis adopt ball screw and flexible direct design, without blacklash and belt drive issues.

High Rigidity 90°Angle Head

Self-manufactured gearbox with powerful 2-step gear transmission provides high torque for both vertical and horizontal machining.

The gearbox with oil cooling lubrication that prevents temperature rise and noise.

High rigidity octagonal milling head design

Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat.

Large diameter toothed clutches provide high machining stability, precision and rigidity.

4 independent pull studs with high clamping force

90° angle head anti-drop safety mechanism

Optional coolant through spindle (CTS) for both vertical/ 90°angle head

Catalogs

No catalogs are available for this product.

See all of YCM (Yeong Chin)‘s catalogsOther YCM (Yeong Chin) products

Double Column Vertical Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.