- Machine-tools

- Machining Center

- 3-axis machining center

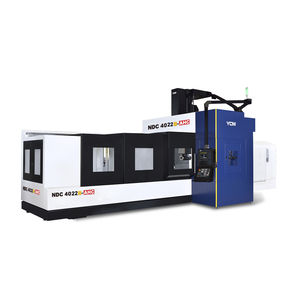

- YCM (Yeong Chin)

3-axis CNC machining center NDC4018B-AHCverticaldouble-column40 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- double-column

- Number of tool stations

- 40 tools, 60 tools

- Other characteristics

- high-precision, high-rigidity, with automatic tool changer

- X travel

4,200 mm

(165.35 in)- Y travel

2,200 mm

(86.61 in)- Z travel

762 mm, 1,016 mm

(30 in, 40 in)- Rotational speed

6,000 rpm

(37,699 rad.min-1)- Power

35 kW

(47.59 hp)- Work feed X-axis

15,000 mm/min

(10 in/s)- Work feed Y-axis

20,000 mm/min

(13 in/s)- Work feed Z-axis

15,000 mm/min

(10 in/s)- Table load capacity

12,000 kg

(26,455 lb)- Tool weight (max)

20 kg

(44.1 lb)- Weight

36,000 kg

(79,366.41 lb)

Description

Self-manufactured gearbox provides high torque for both vertical and horizontal machining

High rigidity octagonal milling head design

Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat

Large diameter toothed clutches provide high machining stability, precision and rigidity

4 independent pull studs with high clamping force

90°angle head anti-drop safety mechanism

Optional coolant through spindle (CTS) for both vertical/ 90°angle head

Reliable AHC Vertical / Horizontal Automatic Tool Change

Rotary head chamber design reduces space and provides rapid head change

Automatic vertical / horizontal head change mechanism

Reduce time for both fixture producing and workpiece installation, improving production efficiency

Multi-face machining in one step increases machining efficiency and precision

Vertical / Horizontal tool change system provides fast tool change, sensors and sequence scanning ensures tool change stability

Catalogs

No catalogs are available for this product.

See all of YCM (Yeong Chin)‘s catalogsOther YCM (Yeong Chin) products

Double Column Vertical Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.