- Machine-tools

- Machining Center

- 3-axis machining center

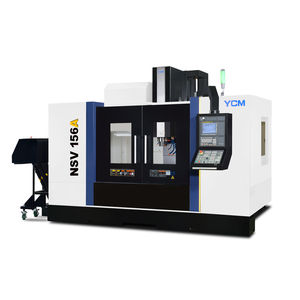

- YCM (Yeong Chin)

3-axis CNC machining center NXV600AverticalBBT4024 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- BBT40

- Number of tool stations

- 24 tools

- Other characteristics

- high-precision, high-rigidity

- X travel

600 mm

(23.62 in)- Y travel

410 mm

(16.14 in)- Z travel

450 mm

(17.72 in)- Rotational speed

12,000 rpm, 15,000 rpm

(75,398 rad.min-1, 94,248 rad.min-1)- Power

18.5 kW

(25.15 hp)- Work feed X-axis

48,000 mm/min

(31 in/s)- Work feed Y-axis

48,000 mm/min

(31 in/s)- Work feed Z-axis

48,000 mm/min

(31 in/s)- Table load capacity

300 kg

(661 lb)- Tool weight (max)

6 kg

(13.2 lb)- Tool-changing time

1.8 s

- Weight

3,000 kg

(6,613.87 lb)

Description

YCM In-house IDD Spindle

Tool unclamping cushion extends spindle bearing life by protecting spindle bearing from tool unclamping force.

Spindle cooling system (opt.) removes heat efficiently and minimizes thermal deformation.

Ceramic bearings features low inertia mass, low centrifugal force, high rigidity and low coefficient of thermal deformation.

High precision helical springs features high dynamic balance and low vibration.

FEM analysis is adopted to ensure the best mass arrangement and rib construction of the machine for constant stability under the intensive load of heavy-duty cutting.

Direct drive provides backlash free, best accuracy, reliability and stability.

All axial AC servo motors equipped with Absolute Positioning Encoders, no zero return needed

The rigid body construction makes for uncompromising precision and rigidity.

High Stability Tool Magazine

Absolute encoder ATC system provides high stability and speed.

Inverter controlled, prevents tool change speed from changing under different power supply frequency.

Automatic Tool Magazine Door Design

Driven by pneumatic cylinder.

Prevent coolant and chips from entering tool magazine.

rand New Exterior Design

Full enclosure exterior (including top cover).

Convertible side window for convenient chip removal.

Aesthetic rear cover design.

Coolant shower for efficient chip removal

Catalogs

FP Series

12 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Cutting CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.