- Machine-tools

- Cutting Tool

- Indexable insert milling cutter

- YIH TROUN CUTTING TOOLS GMBH

- Products

- Catalogs

- News & Trends

- Exhibitions

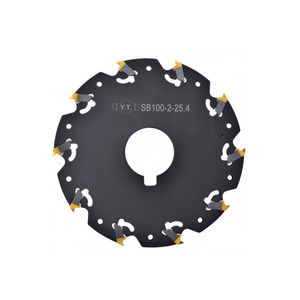

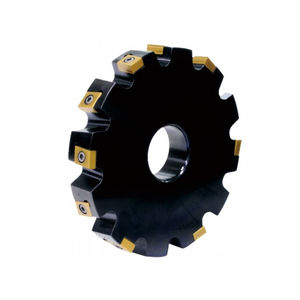

Indexable insert milling cutter SBL faceclampingcutting

Add to favorites

Compare this product

Characteristics

- Construction

- indexable insert

- Type

- face

- Other characteristics

- clamping, cutting

- Diameter

Min.: 80 mm

(3.15 in)Max.: 160 mm

(6.3 in)- Rotational speed

17,200 rpm

(108,070.79 rad.min-1)

Description

Indexable saw milling cutter can not only save inventory cost of cutting tools, but also enhance the stability of cutter by center square positioning design, connection in cutter and holder, as wells as locking with 4 screws. Through the modular adaptor holder design, end user can use their current face milling arbor. Such kind of combined cutter has non-protruded flat bottom and will not cause the issue of interference with bottom.

By using our patented insert clamping design, YIH TROUN has developed indexable saw blade of thickness 1.0mm. The geometry design of insert can lead to effective chip evacuation and reduce heat generation during machining. End user can order inserts of various geometries and grades according to their machining requirements without the necessity to replace the cutter body.

Patented indexable saw blades are developed by YIH TROUN, which has already effectively reduced machining cost for end user in over 40 countries and enhance their competitive advantage. Aided industries include aerospace, medical parts, electronics, traffic industry and nuclear industry, etc.

Features

Safe and reliable insert clamping design. Swedish customer certified that insert can still work firmly under max.

Patented chip evacuation design, no need to worry that chips block within the groove.

Indexable carbide insert for easy replacement. Same cutter is allowed to replace with over 10 kinds of insert.

Using face milling arbor.

Flat cutter bottom without interference.

VIDEO

Other YIH TROUN CUTTING TOOLS GMBH products

INDEXABLE SLITTING / SLOTTING / CUT-OFF SERIES

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- Coated milling cutter

- Cast iron milling tool

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Roughing milling tool

- Helix angle milling cutter

- Indexable insert milling tool

- Corner radius milling tool

- Aluminum milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.