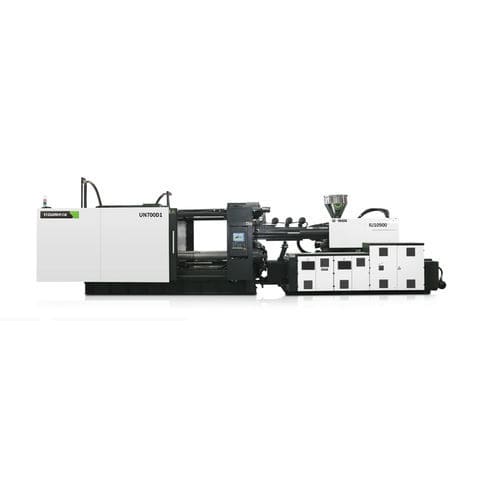

The YIZUMI Advanced Series, with cutting-edge German technology and extensive expertise, leads in large-tonnage two-platen injection molding machines. Our innovative approach aims to set a benchmark in this transformative field.

≤3% Smaller variation of force on tie bar

55% Shorter dry cycle

≤3‰ Outstanding injection stability

Clamping Unit

Impact-proof synchronized lock nut mechanism

Impact-cushioning synchronized lock nut closing is fast and more reliable with low noise.

Independent high-pressure cylinder

Mold opening under high pressure for standard. Large opening force can solve molding problems of deep-cavity products or car lights which are strongly coated on mold or have difficulty in mold opening.

Highly-rigid accurate guide device

Long movable platen supports and L-shape guide rails on machine frame facilitate high load-bearing, guide capacity, and anti-roll adjustment.

Injection Unit

Ultrasonic displacement sensor

Ultrasonic displacement sensor for position measurement is characterized by absolute value, little signal interference, long service life and high accuracy of measurement.

Adaptive PID temperature control

With the use of durable ceramic heater bands and adaptive PID control performed by the Austrian controller, temperature control accuracy is up to ±0.5℃.

Excellent injection performance

Repeatability of injection end position up to ±0.2mm and repeatability of part weight ≤3‰ meet the needs of increasing efficiency and lowering costs.

Servo system driven by fully oil-cooled two-headed motor

- The fully oil-cooled two-headed motor-driven servo system is the quintessence of highly-integrated servo pump