- Power Transmission - Mechanical components

- Mechanical Transmission

- Hydraulic clamping system

- Yueqing Top Electric Science Co.,Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

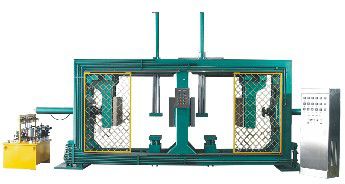

Hydraulic clamping system TEZ-60IIelectricmachiningautomatic

Add to favorites

Compare this product

Characteristics

- Type

- hydraulic, electric

- Applications

- machining

- Other characteristics

- automatic, adjustable, vertical, horizontal

Description

Epoxy resin automatic pressure gelation(APG) clamping machine is combined with hydraulic station and electric panel to produce epoxy resin insulation parts, like support insulator, insulating sleeve, contact spouting bushing, current transformer, voltage transformer etc. It features moulding, pressure holding, top core pulling, bottom core pulling, side injection, vertical and horizontal axis tilting, heating and automatic PID temperature control etc., suitable to be used for various epoxy resin insulators production.

• Hydraulic and Electric system welded to the frame, convenient for transportation

• Bottom core glider designed for durability & clean purposes

• Stainless leakage-collecting tray

• Top core stabilization structure design

• Enlarged top carriage stoke for mold hoist

• Tipping device in both X and Y axes

• Annealing treatment of the main frame

• Flat bottom board for easy access

• Large opening distance for easy unloading & loading

• Large Elliptical installation holes of top and bottom cores, adjustable for mold fixing

• Safety grid and relay, avoiding accidents

Other Yueqing Top Electric Science Co.,Ltd. products

APG Clamping Machine

Related Searches

- Clamp

- Hydraulic clamping device

- Hydraulic clamping system

- Machining clamping system

- Automatic clamping system

- Manually-controlled clamping system

- Vacuum clamping system

- Adjustable clamping system

- Vertical clamping system

- Horizontal clamping system

- Compact clamping system

- Electric clamping system

- Injection mold clamping system

- Stainless steel clamping system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.