- Production Machines

- Plastics Processing

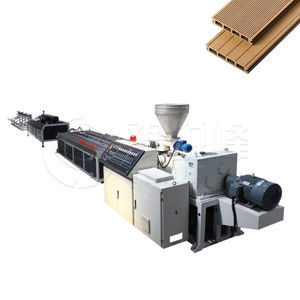

- Profile extrusion line

- Yurefon Machinery(Zhangjiagang) Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Plastics recycling extrusion line YF seriespanelplastic profilefor wall panels

Add to favorites

Compare this product

Characteristics

- Type

- panel, plastic profile, plastics recycling, for wall panels

- Treated material

- for thermoplastics, for PVC

Description

Plastic Profile Board PVC Ceiling Wall Panel Extruder Extrusion Making Machine

Application product PVC Ceilings & Panels

1. Self-fire extinguishing, non-flammable.

2. It is inpenetrable by insects and termites, and won't rot or rust.

3. Resistance to weather/ special chemicals, waterproof/washable.

4. The excellent rigid and superior impacted surface is without any peeling.

5. Natural wood grain: showing authentic wood srtucture and artistic sense.

6. Easy to be cut, drilled, nailed, sawet, and riveted. DIY is all right.

7. Quick maintenance and no need of painting.

8. The simple and fast installation can save a lot of time and manpower cost.

Product Description

Production Flow:

Material →Heating Cooling Mixer →Material Feeding →Conical Twin Screw Extruder →Extrusion Mould & calibrator → Cooling →Printer → Haul-off Unit →cutter →stacker

Equipment Features:

For extruder Temperature Control system,Digital PLC control or Manual Temperature Control Meter

Easy Operation,Reliable performance,High Extrusion Efficiency,Easy Maintenance

Machine list

Feeder:

• To feed material into extruder;

Extruder: -

•World famous brand electrical component: Siemens, Schneider, ABB etc;

• High torque gearbox with adopts NSK/SKF bearing;

• Siemens/WEG original motor achieved global after service;

• Bimetallic screw and barrel;

• Intelligent PLC controlling system with human-friendly interface.

Die head: -

• 3Cr13/3Cr17 material

• Complete set include extrusion die head, calibrator and cooling tank

• Adopt to single, co-extrusion, foam imitation marble profile

Calibration table:

• Include full set of vacuum and water pump

• Width: 240mm

• Length: 6000mm

Other Yurefon Machinery(Zhangjiagang) Co., Ltd. products

Plastic Extrusion Machine

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Rotor pelletizer

- Panel extrusion line

- Pipe extrusion line

- Plastic pelletizer

- PVC extrusion line

- HDPE extrusion line

- Plastic profile extrusion line

- Recycling pelletizer

- Crystallizer

- Twin-screw pelletizing system

- Belt conveyor pelletizer

- High-speed granulator

- PP pelletizer

- PE pelletizer

- Hydraulic pelletizer

- PVC pelletizer

- Plastic crystallizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.