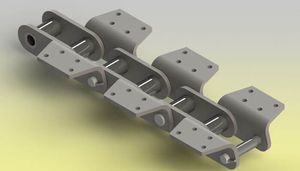

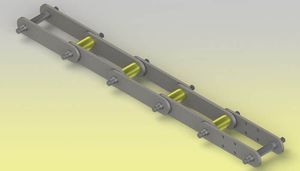

Metal conveyor chain linkfor the food industryslaughterhouse

Add to favorites

Compare this product

Characteristics

- Material

- metal

- Configuration

- link

- Applications

- for the food industry

- Other characteristics

- slaughterhouse

Description

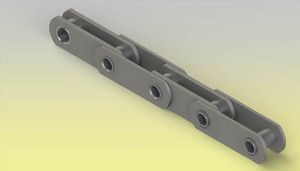

Chain applications in abattoirs on an industrial scale require technologically advanced solutions and materials suitable for the conditions in which transportation takes place. Generally the chains operate in humid environments at least for part of their path. As part of a food system, they are subject to frequent cleaning cycles carried out with chemically aggressive detergents and disinfectants. Frequently the conveyor goes through significant thermal jumps with passages from room temperature to areas where the temperature drops below zero.

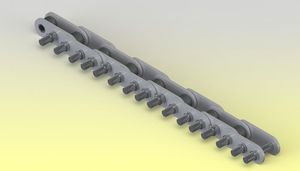

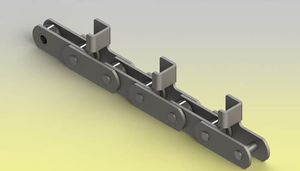

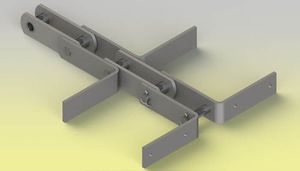

To follow the complex paths required by the process, many of these chains are made with cardan joints. The presence of a hook or a pusher is another frequent feature in chains for slaughterhouses, this element allows the carcasses to be pushes along the guides from which they are hung during the various stages of the slaughtering process.

Numerous chains are used in this sector, there are self-lubricating or low-maintenance versions are available.

Catalogs

No catalogs are available for this product.

See all of Z.M.C. SRL‘s catalogsRelated Searches

- Transfer chain

- Metal conveyor chain

- Steel transfer chain

- Slatted conveyor chain

- Link conveyor chain

- Roller transfer chain

- Canning industry conveyor chain

- Attachment conveyor chain

- Stainless steel conveyor chain

- Conveyor chain for the food industry

- Accumulation conveyor chain

- Roller conveyor chain

- Heavy load conveyor chain

- Lube-free conveyor chain

- Conveyor chain for the steel industry

- Conveyor chain for the beverage industry

- Hollow-shaft conveyor chain

- Conveyor chain for the cement industry

- Conveyor chain for the wood industry

- Conveyor chain for the automotive industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.