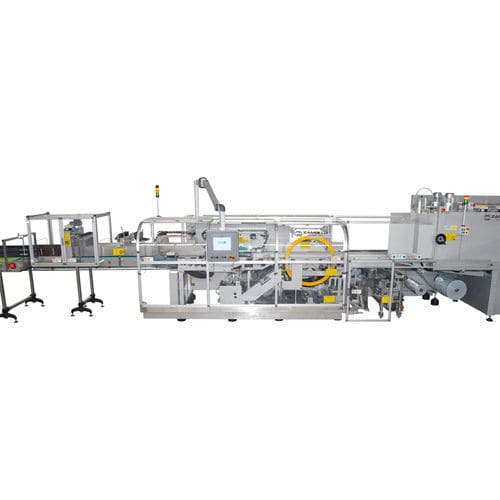

Shrink wrapping machine with shrink tunnel LFTautomaticfor boxesfood

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product applications

- for plastic bottles, beverage, for cans, for boxes, food

- Other characteristic

- with shrink tunnel

Description

The LFT Film only model is available in single, double and triple lanes.

It can package all products characterized by good stability and low risk of damage, including plastic bottles, food cans, beverage cans, clusters and boxes.

The products will be protected from external agents, easy to store and transport and visually pleasing if displayed on store shelves.

Energy saving tunnel

The shrink tunnel present in all Zambelli Shrinkwrap machines has 7 fundamental characteristics:

1. Tunnel flow setting through adjustable holes

2. Extra resistors already installed (zero downtime replacement)

3. Minimum energy consumption

4. Three possible configurations on the same tunnel (1, 2 or 3 lanes)

5. Separate cooling section at the exit for best shrink

6. Tunnel adjustment according to the film characteristics

7. Possibility of working with different types of films by adjusting the air flows and temperature

On the Zambelli shrinkwrappers it is possible to take advantage of an automatic motorized adjustment of the product guides in the areas normally adjustable by means of a handwheel for format change.

All the moving parts of the machine that are subject to format change can be equipped with brushless motors for quick format change.

For easier access by the operator, the reel holder and the manual 90 ° welder are placed on the side of the machine.

In machines that have an automatic welder, in case of use of printed film, a photocell stops the unwinding near the reference notch printed in the film, in order to proceed with the welding between the exhausted reel and the new one.

Catalogs

Related Searches

- Palletizer

- Shrink wrapper

- Automatic sleeve wrapping machine

- Automatic palletizer

- Case packer

- Robotic palletizer

- Automatic case packer

- Cardboard box/case erector

- Shrink wrapper with shrink tunnel

- Cartoner

- Automatic cardboard box/case erector

- Case palletizer

- Horizontal case packer

- Sleeve wrapping machine with sealing bar

- Bottle shrink wrapping machine

- Heat-shrink film shrink wrapper

- Horizontal cartoner

- Adhesive tape cardboard box/case erector

- Palletizer for the packaging industry

- Bottle case packer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.