- Packing - Handling - Logistics

- Packing and Packaging

- Automatic skin-pack machine

- Zappe Packaging Technology GmbH & Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

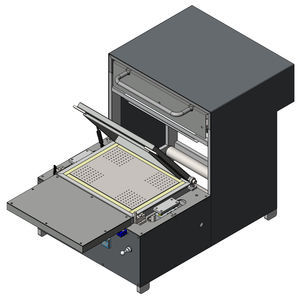

Automatic skin-pack machine SKAsemi

Add to favorites

Compare this product

Characteristics

- Options

- automatic, semi

Description

The Skin Packaging Machine Basis is a mobile unit on lockable swivel castors. With this skin packer, the entire skin process is possible without the use of tools. The standard features includes a heating control with solid state relay, a barely audible ejector vacuum pump with high vacuum performance and an a built-on impact shears for trimming and separating the finished skins. The technology of the skin machine has a modular design and can be expanded step by step.

• Mobile system on lockable swivel castors

• Low-noise and (almost) maintenance-free high-performance vacuum pump

• Loading table with integrated skin-board repository

• Manual pusher for easier infeed of the skin-board into the skin machine

• Attached impact shears for trimmingthe finished packages

• Pneumatically operated safety door in plexiglas design

• Automatic operation after start-up

• Energy-saving heating with short heating time

• Electronic and wear-free control of the heating temperature

• Functional sequence with Programmable Logic Controller (Siemens S7 - 1200)

• Electronic touch panel with color display

• Continuous setting of the time parameters to the 1/10-second for reproducible results

• Timer for stand-by function: if the system is not needed, the heater switches off for energy saving

• Restart after new goods supply

• Energy saving up to 60%

• Extensive thermoforming kit for the production of thermoformed parts

• Pneumatic punching device for euro hole or other punching

• Roller conveyors for knotting particularly heavy parts

• Acceleration of cycle time by installing a vacuum tank

• Increased working space to 250 mm

Other Zappe Packaging Technology GmbH & Co. KG products

Skin Packing Machines

Related Searches

- Packing machine

- Automatic packing machine

- Packing machine for the food industry

- Vacuum packing machine

- Film packing machine

- Bell type packing machine

- Sealer

- Bag packing machine

- Packaging machine for the food industry

- Medical packing machine

- Thermoformer

- Automated thermoforming machine

- Horizontal packing machine

- Semi-automatic packing machine

- Packaging machine for the pharmaceutical industry

- Packaging thermoformer

- Compact packing machine

- Granular packing machine

- Manual packing machine

- Roll-fed thermoformer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.